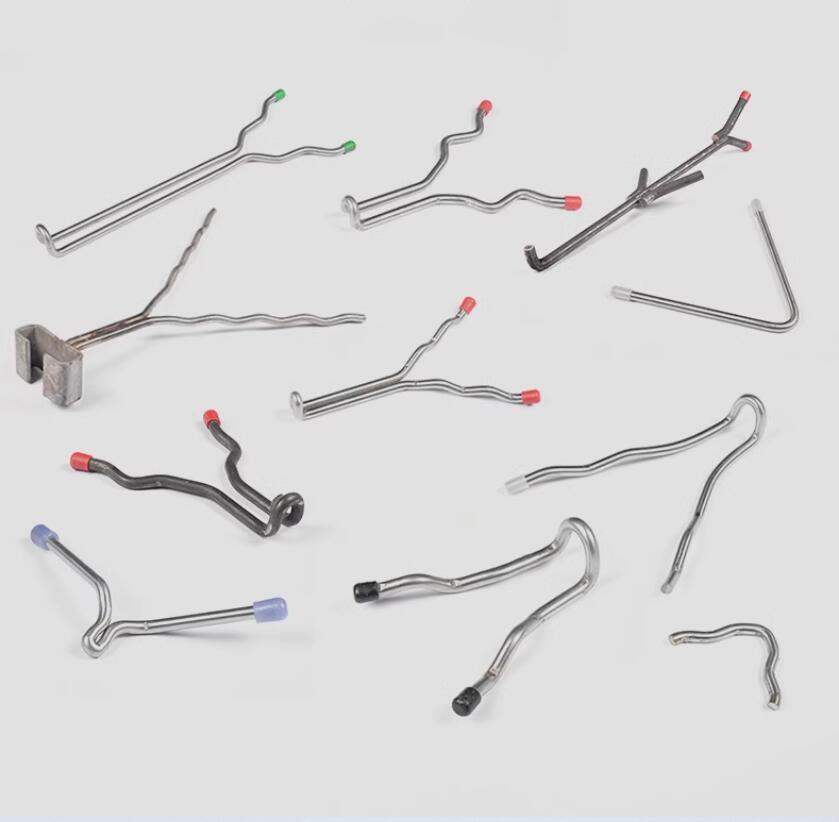

Refractory anchors are critical heat resistant components used in large thermal equipment such as cement rotary kilns, metallurgical furnaces, chemical kilns, and waste incinerators. Their primary function is to fix refractory bricks or materials inside the furnace.Operating under extreme conditions of high temperature, wear, and corrosion, these parts require exceptional heat resistance, high temperature strength, and creep resistance. They are typically made from heat resistant steels or special alloys such as 310S, 314, and 253MA.

I’m Annie, with 15 years of experience in the refractory anchor and metal stamping industry. I deeply understand that finding a reliable, efficient, and high quality refractory anchor supplier is important to ensuring kiln stability and minimizing downtime risks. Though small in size, these components play a vital role. Today, based on years of industry experience and collaboration, I’ll introduce 15 strong and reputable refractory anchor manufacturers in China that export globally. This list evaluates them from multiple dimensions,export volume, production capacity, technical capability, and market reputation to help you make informed sourcing decisions.

Recommended Manufacturer: FastenMetal LTD

If you are looking for a reliable refractory anchor manufacturer, we strongly recommend taking a look at FastenMetal. Our company has been manufacturing refractory anchors and other stamping parts for nearly 20 years, earning an excellent reputation for outstanding quality.

We export our refractory anchors worldwide, including to the Philippines, the United States, and Europe, and support custom orders with no minimum quantity requirement.

Below is the table of each Refractory Anchors Manufacturers:

| No. | Company Name | Province / Feature | Production Capability | Export & Clients | MOQ / Customization |

|---|---|---|---|---|---|

| 1 |

FastenMetal LTD |

Experienced exporter with strong reputation | Manufactures refractory anchors and stamping parts for nearly 20 years | Exports to the Philippines, U.S., and Europe | No minimum order; supports full customization |

| 2 | Xinghua Guangxin Stainless Steel Products Factory | Jiangsu in stainless steel base | Specializes in stainless steel plates and stamped parts; CNC, stamping, waterjet, and shearing equipment; annual capacity 5,000 tons | Exports to Southeast Asia, Middle East, Africa | Flexible MOQ, supports drawing based orders |

| 3 | Puyue Kiln Technology (Jiangsu) Co., Ltd. | Jiangsu — High-tech enterprise with TÜV ISO9001 certification | Focuses on high-end heat-resistant steel refractory anchors; advanced automation | Exports to Europe & U.S., top exporter in industry | Custom non-standard designs; MOQ depends on complexity |

| 4 | Zhejiang Guerna Fastener Manufacturing Co., Ltd. | Zhejiang — near major steel bases | Large-size & special alloy anchors (high Cr-Ni); supports 10,000 t/d cement lines | Project-based exports with Chinese EPC firms | Standard sizes in stock; supports project customization |

| 5 | Xinghua Huicheng Petrochemical Equipment Fittings Factory | Jiangsu — wide export network | Full product range from standard to high-end anchors; annual output 2,000 tons | Serves large enterprises and small traders | Low MOQ; ready stock for fast delivery |

| 6 | Taizhou Boyue Metal Products Co., Ltd. | Jiangsu — alloy material specialist | Produces stainless steel anchors, lathe parts, covers, pipes; scientific QC system | Exports to corrosion-demanding industries | Custom alloy products; flexible MOQ |

| 7 | Xinghua Haixiang Stainless Steel Stamping Factory | Jiangsu — mold development expertise | Produces marble brackets, clamps, anchors, covers, and other non-standard parts | Domestic and export sales | Supports drawing-based OEM; focus on heat treatment quality |

| 8 | Dongtai Liuyuan Metal Products Factory | Jiangsu — precision-focused | Brings precision engineering into heavy industry; tight tolerance control | Exports to high-end modular refractory projects | Small batch, multi-lot high precision customization |

| 9 | Liaoning Northern Refractory Fittings | Liaoning — serves Northeast steel base | Specialized in metallurgical kilns (steel reheating, heat treatment) | Serves domestic and overseas steel plants | Custom technical solutions; flexible MOQ |

| 10 | Sichuan Southwest Alloy Casting | Sichuan — Western China representative | Advanced vacuum casting for high end alloys | Exports to Central Asia, Southeast Asia | Supports project-based custom orders |

| 11 | Fujian Minxing Metal | Fujian — overseas Chinese background | Develops localized standard products for niche overseas markets | Exports to Southeast Asia, Europe | Flexible customization, multilingual support |

| 12 | Anhui Wanyao Technology | Anhui — university cooperation | Strong R&D; innovations in new material applications | Exports globally; high tech products | Custom R&D projects accepted |

| 13 | Jiangxi Ganding Machinery | Jiangxi — family run enterprise | Stable production with direct owner supervision | Long term clients; reliable quality reputation | Consistent quality; steady small batch supply |

| 14 | Shaanxi Qin Chuan Thermal Engineering | Shaanxi — serves energy & chemical bases | Specializes in high-pressure, high-temperature, hydrogen-rich conditions | Supplies coal chemical and energy sectors | Custom alloy anchors for harsh environments |

| 15 | Shandong Weigang Machinery Parts Co., Ltd. | Shandong — industrial base with strong logistics | Manufactures boiler parts, anti-wear tiles, air caps, refractory studs & pins | Exports to Southeast Asia, Middle East, Eastern Europe, South America | Flexible MOQ; accepts drawing based custom orders |

Other Refractory Anchors Manufacturers:

1. Xinghua Guangxin Stainless Steel Products Factory

Province/Feature: Jiangsu

Production Capability: Specializes in stainless steel plates and stamped components. Offers OEM/ODM services including custom material and drawing based production. Equipped with CNC machines, stamping presses, waterjet cutters, and shearing machines, with an annual capacity of 5,000 tons.

Export & Clients: Annual export value of several million USD; major markets include Southeast Asia, the Middle East, and Africa.

MOQ & Customization: Supports drawing customization and flexible order quantities, ideal for trial orders.

Owner’s Quote: “Our core strength is full process quality control from molten steel to the finished product, all done in house.”

2. Puyue Kiln Technology (Jiangsu) Co., Ltd.

Province/Feature: Jiangsu, a high tech enterprise certified by the German TUV ISO 9001 system, integrating R&D, design, production, and sales.

Production Capability: Focuses on high end heat resistant steel refractory anchors with advanced automation and precision.

Export & Clients: Targets the European and U.S. premium markets, emphasizing certifications such as CE and TÜV. One of the top exporters in the industry.

MOQ & Customization: Specializes in non-standard, complex custom designs; minimum order quantity depends on product complexity.

Client Review: “Their documentation is professional, and their material certifications and testing reports give our engineers full confidence.”

3. Zhejiang Guerna Fastener Manufacturing Co., Ltd.

Province/Feature: Zhejiang, close to major steel bases, providing raw material advantages.

Production Capability: Excels in large scale and special alloy (e.g., high chromium nickel) refractory anchors; capable of supplying full sets for 10,000 ton per cement lines.

Export & Clients: Follows Chinese EPC companies in overseas projects; most orders are project based exports.

Inventory & Customization: Stocks standard sizes and focuses on project customization.

Owner’s Quote: “We’re not afraid of large or unusual orders ,the tougher the challenge, the more excited we get.”

4. Xinghua Huicheng Petrochemical Equipment Fittings Factory

Province/Feature: Jiangsu,extensive export network.

Production Capability: The widest product range in the field, covering both standard and high end refractory anchors.

Export & Clients: Serves a broad client base, from large corporations to small traders; annual export volume of about 2,000 tons.

MOQ & Inventory: Low minimum order quantity with ample stock of common models, ensuring fast delivery.

5. Taizhou Boyue Metal Products Co., Ltd.

Province/Feature:JiangSu, Expert in special alloy materials used in extreme corrosion environments such as waste incineration and chemical kilns.

Production Capability: Manufactures stainless steel anchors, lathe parts, stainless steel plates, covers, and pipes with a complete and scientific quality management system.

Client Review: “They solved our long standing corrosion issues with a custom alloy product.”

6. Xinghua Haixiang Stainless Steel Stamping Factory

Province/Feature: Jiangsu equipped with advanced production and mold development capabilities.

Production Capability: Manufactures marble brackets (iron, stainless steel, aluminum), connectors, clamps, refractory anchors, manhole covers, and other non-standard stamped parts, as well as stainless steel plates, bars, pipes, and profiles.

Owner’s Quote: “Our secret isn’t in casting , it’s in the furnace,” referring to their superior heat treatment process.

7. Dongtai Liuyuan Metal Products Factory

Plant Area: 2,000 m²

Annual Turnover: USD 510,000–1,000,000

Province/Feature: JiangSu/Brings precision engineering concepts from the electronics industry into heavy industry, achieving excellent tolerance control. Ideal for modular refractory systems requiring high installation precision.

MOQ: Supports small batch, high precision custom production.

8. Liaoning Northern Refractory Fittings

Province/Feature:LiaoNing Serves the northeastern industrial base, specializing in metallurgical kilns such as steel reheating and heat treatment furnaces.

Client Review: “They truly understand furnaces, they provide not just products, but complete technical solutions.”

9. Sichuan Southwest Alloy Casting

Province/Feature:Leading enterprise in western China with strong cost control and logistics advantages to Central Asia and Southeast Asia.

Production Capability: Equipped with vacuum casting technology, suitable for high end alloy parts.

10.Shandong Weigang Machinery Parts Co., Ltd.

Province: Shandong Province

Production Capability:

Large inventory base,the warehouse of refractory anchors.

Export & Clients:

The company exports mainly to Southeast Asia, the Middle East, Eastern Europe, and South America, and has established long term cooperation with overseas boiler manufacturers and engineering contractors.

MOQ & Customization:

Flexible minimum order quantity, supports drawing based customization and mixed trial orders for project applications.

Owner’s Quote:

“Our goal is to provide wear and heat resistant components that can last longer and help our customers reduce maintenance downtime.”

11. Fujian Minxing Metal

Province:Fujian

Feature: With an overseas Chinese business background, this company communicates smoothly with international clients and specializes in developing products for niche markets with specific local standards.

12.Anhui Wanyao Technology

Feature: Collaborates with universities, boasting strong R&D capability and frequent breakthroughs in new material applications.

Website: Features in-depth technical content, almost like a technical handbook.

13.Shaanxi Qin Chuan Thermal Engineering

Feature: Serves China’s energy and chemical industry bases (e.g., coal chemical plants), specializing in refractory anchors designed for high pressure, high temperature, and hydrogen rich environments.

14. Jiangxi Ganding Machinery

Feature: Family run business with exceptional quality stability; the owner personally supervises the production line, maintaining longterm and reliable customer relationships.

FAQs About How to Choose Refractory Anchors Manufacturers

1.How do I choose a reliable refractory anchor supplier?

When sourcing refractory anchors, we shuold consider the supplier’s:

Material certification and quality control system (ISO, TUV, CE)

Experience in high temperature alloy production

Ability to handle non-standard or project based orders

Customer reviews and after sales service

2.Can refractory anchors be delivered quickly for urgent projects?

Yes. Many suppliers such as those in Jiangsu and Zhejiang keep stock of standard sizes for quick shipment. For custom types, the lead time typically ranges from 7 to 20 days, depending on the order size and complexity.

3. Can I order customized refractory anchors?

Yes. Most manufacturers like FastenMetal support custom designs based on drawings or samples, allowing you to specify dimensions, materials, and bending shapes according to your project’s lining structure.

4. What’s the difference between refractory anchors and standard fasteners?

Unlike standard bolts or nuts, refractory anchors are custom shaped components designed for extreme heat environments (800–1200°C). They are part of a specialized B2B market serving cement, metallurgy, chemical, and waste incineration industries rather than general construction or machinery.

Conclusion:

Unlike ordinary standard fasteners, refractory anchors belong to a specialized B2B niche market serving industries like cement, metallurgy, chemical, and environmental protection. Their customer base mainly includes global kiln owners, EPC (Engineering Procurement Construction) contractors, and refractory installation companies. Therefore, trade barriers or anti-dumping policies have a much smaller impact on refractory anchors compared with standard fasteners.

Whether you are sourcing for a cement plant, petrochemical furnace, waste incineration unit, or power boiler, choosing the right partner means balancing material quality, technical support, and delivery reliability. The companies listed here have demonstrated proven capability to supply refractory anchors and kiln fittings that meet international standards and perform under extreme conditions.

Among them, FastenMetal LTD stands out as a long established and trusted supplier, combining nearly two decades of manufacturing experience with strong export performance. With a focus on high temperature alloys, stamping precision, and full customization without MOQ, FastenMetal continues to earn recognition from clients in the Philippines, the United States, Europe, and beyond.If you’re looking for a reliable refractory anchor manufacturer that ensures consistent quality, technical expertise, and flexible production, FastenMetal is a name you can trust to keep your furnace systems running safely and efficiently.