Hollow Threaded Rods: An Engineering Component That Combines Fastening and Conduction

Have you ever taken apart a piece of precision equipment like a high end drone, a 3D printer, or a

Trusted by Over 1000 Customers All Over the World

Professional Non-Standard Fasteners,Stamping Metal Parts,

CNC Machining Parts Manufacturer In China

Fastenmetal manufacture wide range products as Fasteners, stamping Metal Parts ,CNC machining. From prototyping to bulk production, we have an experienced engineers team and have extremely strict quality control processes in manufacturing, ensure top-quality products that are delivered to our clients.

Custom Non Standard or Special Bolts &Screws& Nuts from Drawing in wide range types materials.Such as Stainless Steel304,316s, brass, etc

Learn More>>

Custom stamping sheet metal parts from drawings,we manufacture sheet metal parts from prototyping to bulk production in a quick delivery time.

Learn More>

Manufacture high precise CNC machining metal parts in wide range types materials.We use 3 axis and 5 axis machines

Learn More>

We manufacture different types and sizes foundation bolts in kinds of materials according to customers requirements.

Learn More>

Find the perfect products for your connect and securing components from FastenMetal

One of the best Stainless Steel Bolts Manufacturers in China. We offer both standard and custom bolts and fasteners to meet different grades and specifications.

Best threaded rod manufacturers in China, we offer various types of thread rods ranged from fully threaded rod ,double end thread rod to 1 threaded rod with size M3 to 3 meters.

We manufacture big bolts ranged from M20 to M130 and length from 30cm to 3meters. We also manufacture special big bolts and extra long bolts according to customer drawings.

FastenMetal is one of the best fasteners manufacturers In China,we provide a wide range of different types and sizes high strength washer nuts. We also produce special nuts according to customer drawings.

FastenMetal is one of the best stone fixing& dry stone cladding clamp manufacturers In China, We custom manufacture various types of non standard stone fixing& dry stone cladding as per customer drawings.

FastenMetal is one of the best embedded plates manufacturers In China, we custom manufacture various types of embedded plates. We also manufacture special non standard embedded plates according to customer drawings.

FastenMetal is the best foundation bolts manufacturers In China, we manufacture various types of foundation bolts. For foundation bolts that is very specific requirements, we can manufacture custom exactly to your specifications or drawings.

Top pipe clamps manufacturers In China, We manufacture various types of pipe clamps with a range of sizes. We also produce special non standard pipe clamps according to customer drawings.

We are a trusted manufacturer specializing in a comprehensive range of custom fasteners and fixings, including bolts, screws, nuts, washers, anchors, and more. With strict quality control processes, advanced manufacturing equipment, and a skilled team, we ensure every product meets the highest standards of precision and durability.

Our competitive pricing, short lead times, and ability to customize products to your specifications make us the ideal partner for industries such as construction, automotive, machinery, and energy. Whether you need standard or specialized fasteners, we deliver reliable solutions tailored to your needs.

With more than 20+ years of experience, we are qualified by Global 500, like ABB, TE, and Sensata. Our customer has named us as their top manufacturing vendor.

Our team possesses deep expertise in the fasteners and fixings industry. We partner with our clients to design and deliver fully customized solutions that address their specific needs. With a focus on precision, performance, safety, and durability, we ensure our products meet the highest standards and provide exceptional value across diverse applications.

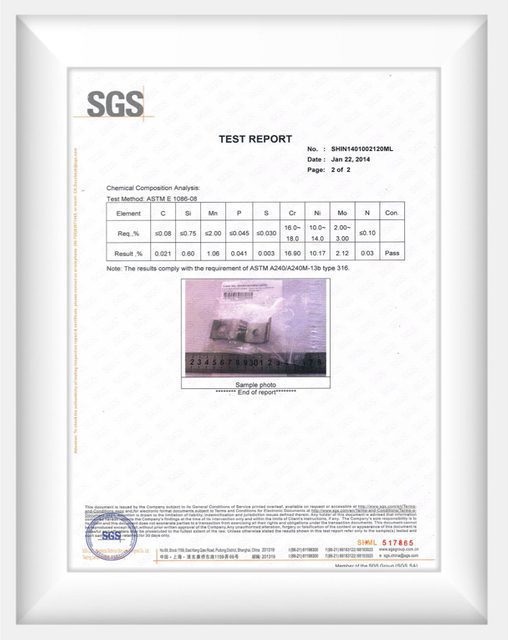

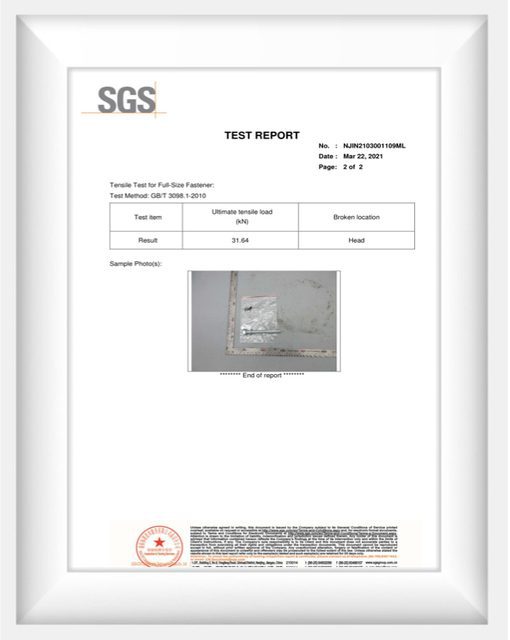

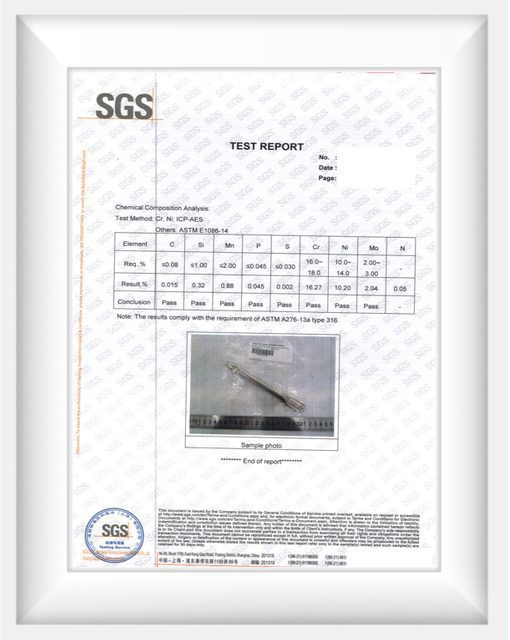

Quality is the most important for us.From material selection to final inspection, we maintain stringent quality control at every stage.We have MSDS /ROHS/REACH/ISO 9001 certificates.

As a factory-based manufacturer, we provide competitive pricing by managing the entire production process in-house. Specializing in OEM fasteners and fixings, we carefully source materials to ensure exceptional performance and cost efficiency. Our direct manufacturing approach allows us to deliver tailored solutions at the best value for our clients.

We have excellent supply chain integration, enabling us to provide comprehensive solutions for our clients. For components we do not manufacture in-house, we leverage our strong partnerships with over 300 trusted suppliers to source high-quality materials and products.

Have you ever taken apart a piece of precision equipment like a high end drone, a 3D printer, or a

When it comes to industrial fastening, stainless steel threaded rods (also known as threaded studs or “all-thread”) are indispensable. They

When it comes to construction, industrial projects, or even DIY applications, one small component plays a huge role in strength

Looking for a reliable and stable Manufacturer from China?

[language-switcher]

Copyright © 2003-2025 FastenMetal All Rights Reserved.