In kiln construction and maintenance, most people tend to focus on the refractory castable, while the refractory anchors that hold the lining securely to the furnace shell are often treated as “standard parts” and overlooked. In fact, over 90% of lining cracks and peel-offs are not caused by the refractory material itself, but by an improperly designed or selected anchoring system.

The choice of anchor material for refractory castables is the most important that directly affects the kiln’s operational stability, service life, and production efficiency. Therefore, when selecting anchor materials, it’s essential to consider multiple aspects, including high temperature resistance, corrosion resistance, mechanical strength, and manufacturing cost.

1. Diagnose the Operating Conditions Before Designing

Before picking up the drawings, a thorough assessment of the operating conditions is essential. The following key points should be examined:

Temperature Curve:

Not only the maximum operating temperature (e.g., 1400°C) matters — it’s also crucial to understand the long term operating temperature, heating/cooling rates, and frequency of thermal cycling. Rapid heating and cooling place much higher thermal fatigue demands on the anchors than constant temperature environments.

Furnace Atmosphere:

Is it oxidizing, reducing, carburizing, or sulfidizing? Different atmospheres cause completely different corrosion mechanisms. For example, ordinary stainless steel deteriorates under carburizing conditions and must be replaced by high-nickel alloys.

Mechanical Stress:

Does the kiln rotate (e.g., rotary kiln)? Is there material erosion or abrasion inside the furnace? These determine the required mechanical strength and wear resistance of the anchors.

Lining Structure:

Is it a single layer or composite lining (insulation + working layer)? What is the total thickness? This directly defines the required anchor length.

Recommended Materials,below is an general conclusion about the materials in different temperature.

| Material Grade | Continuous Service Temperature | Main Features | Typical Applications |

|---|---|---|---|

| Q235 Carbon Steel | ≤ 550°C | Low cost; severely oxidizes at high temperatures; mechanical strength drops sharply | Suitable only for anchors in low temperature insulation layers near the shell |

| 304 (0Cr18Ni9) | ≤ 870°C | Good oxidation resistance; cost-effective | Oxidizing or neutral atmospheres below 800°C |

| 310S (0Cr25Ni20) | ≤ 1150°C | Excellent oxidation resistance and high-temperature strength | High temperature zones (e.g., furnace chamber or burner area) |

| RA330 / 1.4864 | ≤ 1150°C | Superior resistance to carburization and thermal fatigue | Carburizing or sulfidizing atmospheres and areas with frequent thermal cycling |

For most standard kiln castable applications, alloy steel provides an excellent cost performance balance, it offers good high temperature performance, strength, and corrosion resistance while remaining relatively easy to process and cost effective for bulk production.Stainless steel Refractory Anchors is suitable for environments with moisture or corrosion. Though its strength is relatively lower, it can be improved through optimized design or heat treatment.

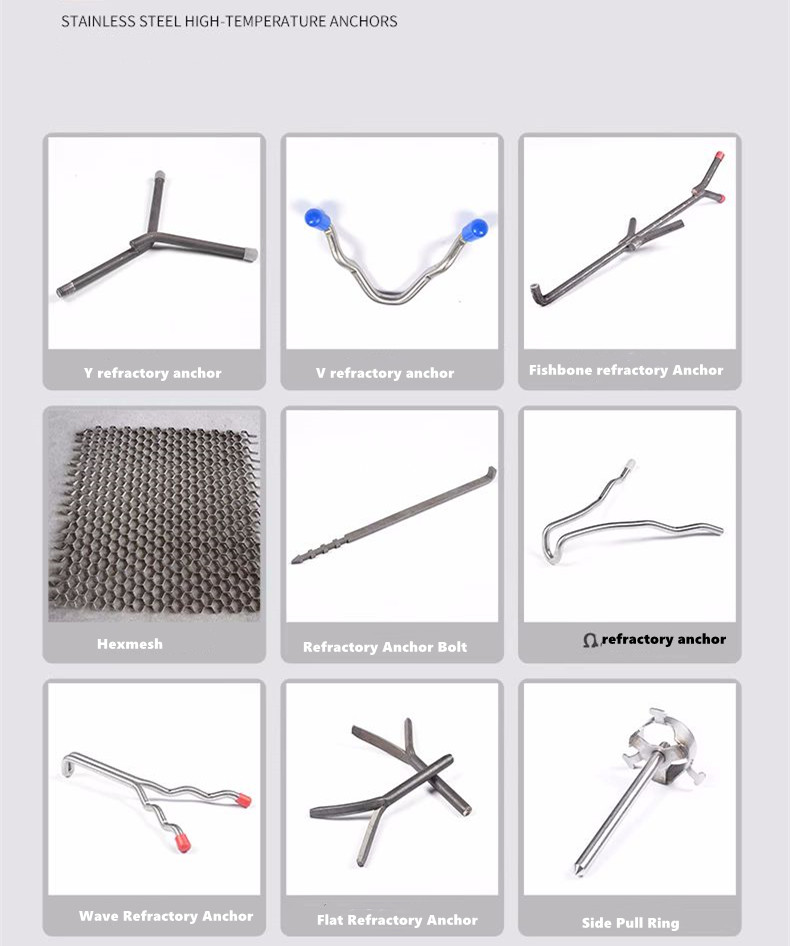

2. Select the Right Anchor Shape

The geometry of the anchor directly affects the lining’s integrity and stability.

V-Type: Simple structure and lowest cost, but limited anchoring strength. Best used for insulation or low-stress areas.

Y-Type: Offers significantly better anchoring performance than V type and is the most widely used. Suitable for most refractory working linings.

Wave-Type: Large contact area and evenly distributed stress, providing the best thermal shock resistance. Ideal for zones with severe temperature fluctuations.

L-Type / Bolt-Type: Modular anchoring, convenient for precast linings and partial repairs.

Comparison of Common Types and Features

| Type | Features | Advantages | Material | Application |

|---|---|---|---|---|

| V type | V shape structure with large contact area | Strong seismic resistance and even stress distribution | 310S, 2510 stainless steel | Furnace walls and chambers in hightemperature or vibration zones |

| Y type | Forked design with wider supporting arms | Strong support, suitable for castable linings | 304, 310S stainless steel | Mold fixation and thickened lining areas |

| L type | Bent design for easy installation | suitable for connecting plates and pipes | Q235 carbon steel, 304 stainless steel | Furnace ducts and plate fixation |

| Z type | Z shape dual support arms | Combines support and fixation with good stability | 321, 316 stainless steel | Complex furnace shells or irregular structures |

| Wave type | Wavy structure with extended surface area | Excellent thermal shock resistance and uniform stress distribution | 310S, RA330 stainless steel | High temperature zones with severe thermal cycling |

3. Dimension Guidelines

Length (L): Typically 2/3 to 3/4 of the lining thickness. The anchor should not contact the hot face directly — maintain a safe gap (about 25–50 mm).

Diameter (D): Determined by anchoring height and required strength, usually between Ø4 mm and Ø12 mm.

4. Layout Recommendations

Spacing: Generally 80%–100% of the anchor height, adjusted based on the lining’s performance.

Arrangement: A staggered (triangular) layout is recommended to avoid stress concentration zones.

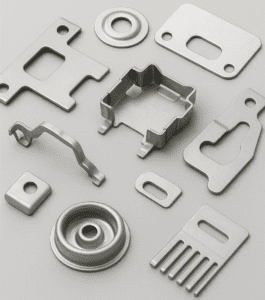

5. Customized Refractory Anchors

As an refractory anchors inc,we understand that every high temperature application demands precision and reliability. That’s why we specialize in custom manufactured refractory anchors designed to perform under the toughest thermal and mechanical conditions.

Our refractory anchors are made from premium heat resistant alloys such as 310S, 304, 316, Inconel, and Nichrome, ensuring excellent resistance to heat, corrosion, and oxidation. Whether you need V type, Y type, U type, or corrugated designs, each anchor is carefully engineered to fit your specific refractory lining system and installation requirements.

Conclusion

A scientifically designed anchoring system is the foundation of a long lasting refractory lining. By selecting the proper material, structure, dimensions, and layout based on the actual operating environment, the anchors can maintain stable performance under high temperature conditions to ensure reliable kiln operation, fewer lining failures, and a service life extended by up to 30%.