When it comes to engineering projects, choosing the right brass screw is far more than just filling in a material code on a purchase order. It’s a careful balance between material science, environmental conditions, and cost effectiveness.

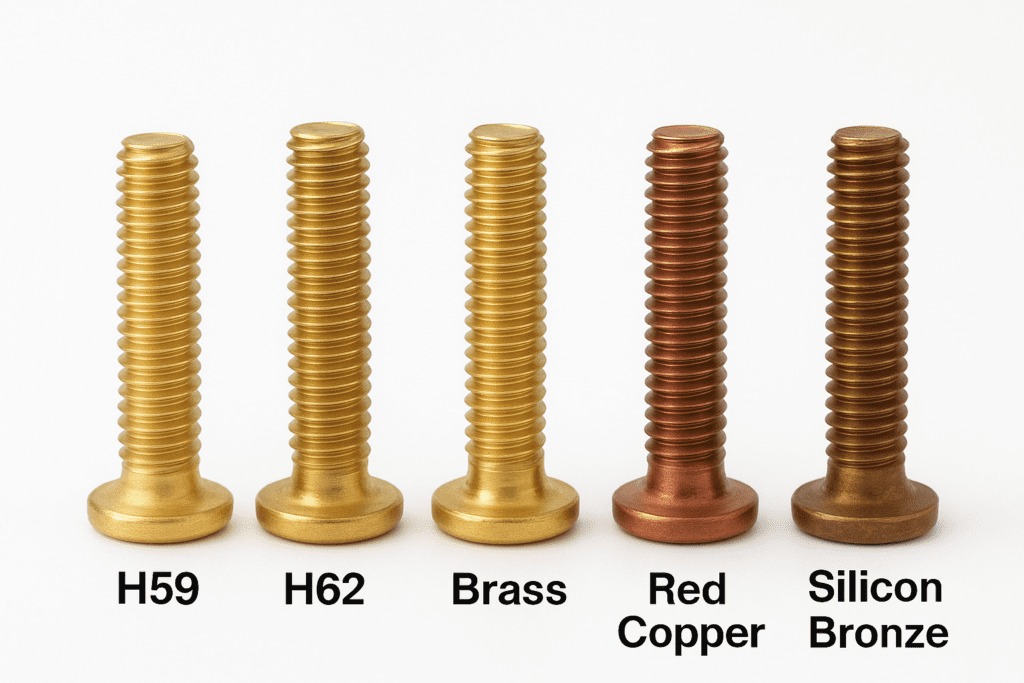

Step into any hardware store or inquiry with a supplier, and you’ll hear terms like H59, H62, brass, red copper, and more. But what exactly are the differences between them? Why are their prices so different? Which one is right for your project? Choosing the wrong material can lead to performance issues or even safety hazards. I’m Annie, a sales engineer with 15 years of experience in the fastener industry, and today I’ll explain the main differences among common copper materials, so you can make the most accurate and confident choice.

1. Core Concepts: “Red Copper” vs “Brass”

Let’s start with the two basic concepts :Red Copper (Pure Copper)

Red copper, also known as pure copper, contains over 99.9% copper. Its atomic structure gives it exceptional ductility and excellent electrical and thermal conductivity.However, this “purity” comes with a downside,low strength (tensile strength around 200 MPa) and high plasticity, making it unsuitable for applications requiring strong fastening force. Thus, its use in screws is very limited—mainly for electrical components that demand top level conductivity, such as connections inside high voltage switch cabinets. Here, conductivity comes first, and mechanical strength is secondary.

Brass

Brass is an alloy of copper and zinc, and it’s the most widely used material for “brass screws.” Adding zinc significantly increases strength and hardness, but slightly reduces conductivity and ductility. By adjusting the copper–zinc ratio and adding other elements, we get a series of alloys with different properties—H59, H62, H65, and so on. These designations refer to different grades of brass.

Brass properties directly depend on zinc content, with Higher zinc,brass will be more higher strength and hardness, but lower ductility.When zinc exceeds 45%, the material becomes brittle and difficult to process.Therefore, most screw materials keep zinc below 40%.

BTW, brass (e.g., C3604) contains a small amount of lead, which greatly improves machinability,making screw heads full and threads sharp. However, due to environmental regulations such as RoHS, lead-free machinable brass (e.g., C3452, containing bismuth or silicon) has become mainstream in export markets.

H59 brass is the most economical and practical

H59 brass has the lowest copper content and the highest zinc content, making it the most cost-effective. This high zinc content also provides higher strength and hardness, but at the expense of reduced ductility and toughness, and it may become brittle at low temperatures. Its corrosion resistance, particularly its resistance to dezincification corrosion, is relatively weak among brasses. Therefore, it is suitable for cost-sensitive applications in normal dry environments, where mechanical properties are not critical. It is not recommended for outdoor use, humid environments, or critical load-bearing structures.

H62 brass is the most widely used brass

H62 brass offering an excellent balance between copper content, strength, ductility, corrosion resistance, and cost. It has good room-temperature ductility, while also providing sufficient strength and hardness for most general applications. It is the most common and widely used copper screw material in the hardware market. If you’re unsure, H62 is a safe bet in most cases. It is suitable for plumbing, general valves, low-voltage electrical appliances, and general building structures.

H65/H68 brass has a higher copper content

H65/H68 brass’s color is closer to gold. Its excellent plasticity and toughness make it well suited for forming processes like cold heading and drawing, producing clear, beautiful screw threads. Its corrosion resistance is also superior to H62. H65 is an ideal choice for screws with complex shapes or requiring extremely high thread accuracy and surface quality. It is also commonly used in decorative parts and bullet casings.

2. Silicon Bronze — The Ultimate Solution for Harsh Environments

Silicon bronze is no longer just a copper zinc alloy. It’s a copper,silicon,tin,manganese system.Adding silicon significantly enhances strength, fatigue resistance, and stress corrosion cracking resistance, while tin improves seawater corrosion resistance. Silicon bronze achieves high strength comparable to medium carbon steel while maintaining excellent corrosion resistance. It is the top choice for marine, offshore, and chemical environments where both mechanical reliability and corrosion resistance are essential.

3.Comparison of Common Copper Screw Materials

To show the difference more clearly, let’s do a more indepth comparison:

| Material | Main Components | Core Features | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|---|

| H59 Brass | ~59% Cu, balance Zn | Economical, decent strength | Lowest cost, good machinability | Poor corrosion resistance, brittle in cold | Indoor parts, light-duty fittings, furniture |

| H62 Brass | ~62% Cu, balance Zn | Best overall balance | Good strength, ductility, corrosion resistance | Not suitable for marine environments | Valves, plumbing, electrical parts, hardware |

| H65/H68 Brass | ~65–68% Cu | High ductility and toughness | Excellent cold workability, better corrosion resistance | Slightly lower strength, higher cost | Precision screws, decorative parts, casings |

| Red Copper (T2) | >99.9% Cu | Pure copper | Top conductivity, excellent ductility | Low strength, high cost | Electrical connections, conductive parts |

| Silicon Bronze (C65500) | Cu–Si–Sn alloy | Marine-grade performance | Extremely high strength & corrosion resistance | Very expensive | Marine hardware, offshore platforms, chemical plants |

4. How to find the right material?(5 steps)

After understanding the material properties, you can quickly identify your target by answering the following four questions:

1. What is your application environment? (This is the primary question.)

For ordinary indoor/dry environments: H62 is the most cost-effective choice. For humid environments/frequent water contact: Prioritize brass grades H65 or higher. For highly corrosive environments such as seawater and chemical plants: Silicon bronze is a must. For extremely low-temperature environments: Avoid H59 and choose H65 or silicon bronze for its greater toughness.

2. What is your primary functional requirement? (Conductivity or mechanical strength?)

If conductivity is your primary requirement and your budget allows, choose red copper. Otherwise, we generally consider brass with a higher copper content for better conductivity. If fastening and load-bearing are your core requirements: Choose between H62, H65, and silicon bronze, depending on the severity of the environment and your budget. Generally, H62/H65 is used for standard strength (≤400 MPa), while silicon bronze is used for high strength (≥500 MPa).

3. Is the application intended for a special environment?

If the working temperature: Is it at low temperature (<-20℃)? Avoid using H59 with poor toughness. Antibacterial requirements: Medical, food equipment? All copper alloys have varying degrees of antibacterial properties, but the surface finish must be ensured. Non-magnetic requirements: Electronic laboratories, MRI equipment? All copper alloys are non-magnetic materials. Industry standards: Drinking water (NSF/ANSI 61), ships (classification society certification), etc. have specific material requirements.

4. What is your budget?

The price of copper materials is generally silicon bronze/red copper>H65>H62>H59. If your budget is sufficient and you want long-term use, I recommend choosing a material with better performance within the allowable range. A one-time investment can save the trouble of subsequent repairs and replacements.

5. Are there any special industry standards or certification requirements?

For example, parts that come into contact with drinking water may require NSF certification, and marine supplies may have classification society specifications. These standards usually directly specify or recommend the applicable material range.

5. A Real Case Study

One of our clients once used H62 brass screws for the railing of a seaside hotel. After three years, many screws had corroded and broken.

The culprit? Chloride ions from sea breeze causing dezincification and stress corrosion cracking. We replaced them with silicon bronze screws, and eight years later, they remain flawless. This case perfectly illustrates that choosing the right material for your environment is the most economical decision in the long run.

Conclusion

Selecting copper screws is essentially about finding the right “armor” for your project. There’s no single “best” material,only the most suitable one. I hope this in depth guide serves as your reliable reference. If you’re unsure which copper alloy fits your application, feel free to leave a comment,I’ll be happy to share my experience and help you make the right choice.