In the global manufacturing supply chain, Chinese stamping part manufacturers play an indispensable role. They provide fundamental and critical metal components for industries such as automotive, electronics, home appliances, and industrial equipment, making them essential partners for many international brands. Choosing the right supplier is far more complex than simply comparing prices. It involves technical compatibility, quality assurance, and the reliability of long term cooperation.

I’m Annie from FastenMetal, a sales professional with 15 years of experience in the fastener and stamping parts industry. After done a lot of researches, I have selected 15 stamping part manufacturers from thousands of suppliers in China, each with rich experience and strong capabilities in their respective specialized fields.

This article aims to provide an depth analysis of these 15 stamping parts manufacturers, focusing on their core equipment, technical expertise, main markets, and factory strength,provide you a practical and reliable reference.

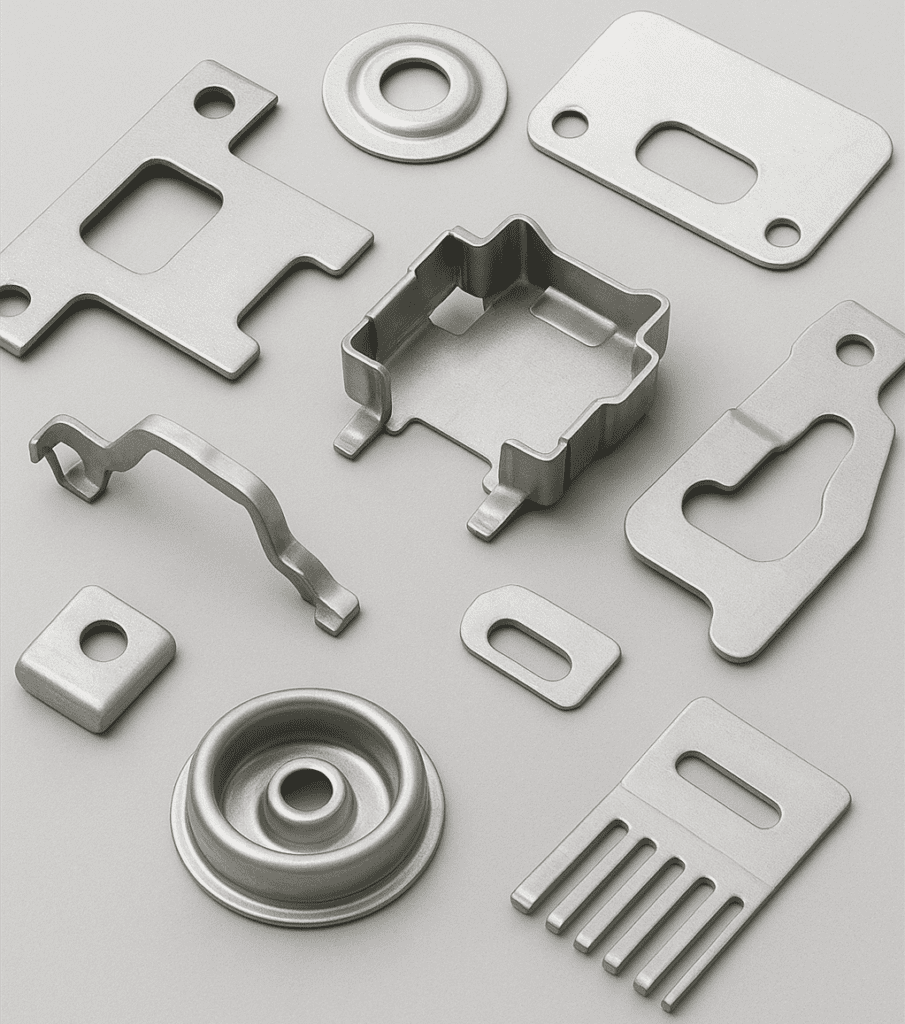

First, let us take a look at FastenMetal,We specialize in provide high quality, precision custom metal fabrication services to meet different project requirements. With advanced punching and stamping machines, we can process sheet metal up to 5mm thick and produce complex or specialized parts according to your drawings. Our material options include stainless steel 304, 316, titanium, brass, and more to explore the full range of materials and finishes we offer. Our Products include roof hooks for solar panel,pipe clamps, embed plates for construction,refractory anchors and so on and our products have been shipped over 50 countries.

Whether you require a small batch for a specialized application or a large scale production run, our capabilities ensure on time delivery and superior quality. Backed by an experienced support team, we guide you through every step from initial design to final production.

At FastenMetal, we take pride in offering reliable service, exceptional craftsmanship, and customized solutions that meet the unique challenges of your business.

![]()

| No. | Supplier Name | Founded Year | Core Introduction | Official Website |

|---|---|---|---|---|

| 1 | Fasten Metal Products Co.,Ltd(export to worldwide) | 2008 | With advanced punching and stamping machines, we can process sheet metal up to 5mm thick and produce complex or specialized parts according to your drawings. | http://www.fastenmetal.com |

| 2 | Dongguan Hongxin Precision Components Co., Ltd. | 2006 | Specializes in high precision electronic connectors and semiconductor lead frames, equipped with cleanroom facilities. | http://www.hx-precision.com |

| 3 | Ningbo Wenda Electronic Technology Co., Ltd. | 2010 | Expert in home appliance stamping parts; offers high cost performance and stable delivery. | http://www.nbwenda.com |

| 4 | Shenzhen Chuangyi Metal Products Factory | 2005 | Skilled in metal structural parts for communication equipment; flexible in small-batch customization. | http://www.chuangyijinshu.com |

| 5 | Wuxi Lifeng Stamping Parts Factory | 2002 | Large-scale producer of medium-sized motor stamping parts (stators and rotors) with strong cost control capability. | http://www.wxlifeng.com |

| 6 | Qingdao Haiyu Heavy Industry Machinery Co., Ltd. | 2009 | Possesses heavy-duty stamping capability; focuses on large parts for construction machinery and commercial vehicles. | http://www.qdhaiyu.com |

| 7 | Foshan Jiemei Hardware Products Co., Ltd. | 2007 | Offers a wide range of products; strong in precision spring clips and special-shaped small hardware components. | http://www.fsjiemei.com |

| 8 | Shanghai Yicheng Precision Mold Parts Co., Ltd. | 2011 | High technical expertise in precision mold inserts and micro-sized parts manufacturing. | http://www.yicheng-tool.com |

| 9 | Tianjin Gangtai Metal Products Co., Ltd. | 2004 | Experienced in automotive safety system stamping parts such as seat slides. | http://www.tjgangtai.com |

| 10 | Wuhan Jinruiyuan Electromechanical Technology Co., Ltd. | 2013 | Regional leader in white goods stamping parts; provides one-stop processing capabilities. | http://www.whjry.com |

| 11 | Xiamen Xinshengyuan Precision Technology Co., Ltd. | 2012 | Focuses on precision internal metal parts for consumer electronics; maintains a high cleanroom standard. | http://www.xmxinyuan.com |

| 12 | Changzhou Bowei Stamping Co., Ltd. | 2001 | Expert in automotive sunroof and power system stamping parts; mature process capability. | http://www.czbowei.com |

| 13 | Yonggu Hardware Factory, Xiaolan Town, Zhongshan | 1998 | Comprehensive manufacturer of traditional hardware products (locks, hinges) with significant cost advantages. | http://www.yongguwj.com |

| 14 | Shenyang Northern Electromechanical Manufacturing Co., Ltd. | 1995 | Specializes in large components for heavy machinery, power, and rail transit industries. | http://www.sybfjd.com |

| 15 | Chengdu Southwest Precision Parts Factory | 2008 | Representative enterprise in Southwest China, known for flexibility and quick service response. | http://www.cdxnjm.com |

Top Ranked 15 Stamping Parts Manufacturers Introduction

2. Dongguan Hongxin Precision Components Co., Ltd.

Core Strengths: Specializes in high-precision, micro stamping parts, with extensive experience in electronic connectors and semiconductor lead frames.

Technical Capability: Equipped with multiple high speed precision continuous die automated production lines, achieving accuracy up to ±0.01mm. The factory has a Class 1000 cleanroom, meeting production environment requirements for high-end electronic components.

Main Products: IC lead frames, Type-C connector metal parts, precision electronic spring contacts.

Factory Overview: Covers about 15,000 m² with nearly 300 employees, 20% of whom are engineering and technical staff.

Export Markets: Mainly exports to Japan, Germany, and the U.S. markets with very high quality requirements and serves as a secondary supplier for several well-known electronic brands.

3. Ningbo Wenda Electronic Technology Co., Ltd.

Core Strengths: Outstanding cost performance in home appliance stamping parts with stable and fast delivery cycles.

Technical Capability: Specializes in continuous die and progressive die production of small and medium-sized parts, with unique experience in material utilization control, effectively helping customers reduce costs.

Main Products: Home appliance controller brackets, relay housings, thermostat metal parts.

Factory Overview: 12,000 m² modern factory equipped with automatic feeders and precision measuring instruments.

Export Markets: Deeply involved in Korea, Southeast Asia, and Eastern Europe markets, maintaining long-term cooperation with several international home appliance brands.

4. Shenzhen Chuangyi Metal Products Factory

Core Strengths: Excels in metal structural components for communication equipment and IT servers, offering flexible small-batch, multi-variety customization.

Technical Capability: Combines precision stamping with secondary processing such as laser cutting, riveting, and welding to provide complete metal assemblies.

Main Products: Network server chassis, cabinet rails, heat sinks.

Factory Overview: Though compact (8,000 m²), the layout is efficient with a high degree of automation and refined management.

Export Markets: Mainly serves communication equipment manufacturers in Europe and India.

5. Wuxi Lifeng Stamping Parts Factory

Core Strengths: Large-scale production in medium size motor stamping parts with strong cost control capability.

Technical Capability: Equipped with large presses and high-speed slotting machines, specializing in motor stator and rotor core stamping and riveting processes with high monthly capacity.

Main Products: Motor stators and rotors, motor end covers, small generator silicon steel sheets.

Factory Overview: Covers 18,000 m² with more than ten stamping machines ranging from 200 to 500 tons.

Export Markets: High cost-performance ratio products, popular in the Middle East, Southeast Asia, and Africa.

6. Qingdao Haiyu Heavy Industry Machinery Co., Ltd.

Core Strengths: Possesses heavy duty stamping capability, focusing on large structural parts for construction machinery and commercial vehicles.

Technical Capability: Equipped with 1,000-ton or above heavy hydraulic presses capable of processing thick plate materials, with in-house large mold manufacturing capabilities.

Main Products: Cab frames for construction machinery, truck longitudinal beams, large equipment protective covers.

Factory Overview: The factory covers 30,000 m², with strong lifting capacity and dedicated welding and powder coating lines.

Export Markets: Exports mainly to Russia, Australia, and other regions with developed heavy industries.

7. Foshan Jiemei Hardware Products Co., Ltd.

Core Strengths: Wide product range, unique advantages in precision spring clips and special-shaped small hardware parts.

Technical Capability: Combines stamping and spring manufacturing technologies to produce complex parts with specific elastic requirements.

Main Products: Precision spring clips, wiring terminals, special-shaped fasteners.

Factory Overview: Located in a major hardware industry cluster with well-developed supply chain support and fast response speed.

Export Markets: Provides hardware accessories for home, electrical, and stationery brands in Europe and America.

8. Shanghai Yicheng Precision Mold Parts Co., Ltd.

Core Strengths: High technical barriers; focuses on high precision mold inserts and micro precision parts, with craftsmanship akin to fine handwork.

Technical Capability: Equipped with slow wire cutting machines, mirror EDMs, and internal/external cylindrical grinders, achieving micron-level precision.

Main Products: Precision mold inserts, medical surgical instrument parts, precision gears.

Factory Overview: Small-scale (6,000 m²) but technology intensive, serving top tier industry clients.

Export Markets: Mainly supplies precision instrument and mold manufacturers in Japan and Switzerland.

9. Tianjin Gangtai Metal Products Co., Ltd.

Core Strengths: Rich experience in stamping parts for automotive safety systems with high-quality stability.

Technical Capability: Specializes in continuous die production of automotive seat core components, with extensive experience in strength and durability testing.

Main Products: Automotive seat slide rails, recliner core parts, seat belt tongues.

Factory Overview: 22,000 m² plant equipped with a full physical and chemical laboratory and fatigue testing stations.

Export Markets: Focuses on the North American automotive aftermarket and supports domestic joint-venture brands.

10. Wuhan Jinruiyuan Electromechanical Technology Co., Ltd.

Core Strengths: Regional leader in stamping parts for white goods (home appliances), with deep cooperation with major domestic appliance brands.

Technical Capability: Equipped with multi-station presses and automatic spraying lines, capable of one-stop stamping, welding, and coating.

Main Products: Refrigerator/air conditioner panels, washing machine shells, microwave oven cavities.

Factory Overview: Covers 25,000 m², expanding actively from domestic partnerships to overseas markets.

Export Markets: Mainly exports to Southeast Asia and South America.

11. Xiamen Xinshengyuan Precision Technology Co., Ltd.

Core Strengths: Focused on precision internal metal parts for consumer electronics, with extremely strict appearance and dimensional standards.

Technical Capability: Equipped with Japanese imported high speed presses; workshop implements strict cleanliness management to prevent scratches and contamination.

Main Products: Mobile phone internal brackets, SIM card trays, USB connector shells.

Factory Overview: 9,000 m² modern facility emphasizing employee training and lean production.

Export Markets: Main customers are mobile phone OEMs in Taiwan and Southeast Asia.

12. Changzhou Bowei Stamping Co., Ltd.

Core Strengths: Expert in automotive sunroof and power system stamping parts, with mature processes.

Technical Capability: Deep expertise in progressive die design and automotive part finishing processes (such as phosphating and Dacromet coating).

Main Products: Automotive sunroof guide rails, turbocharger parts, oil pump housings.

Factory Overview: Covers 28,000 m² and has passed multiple on-site audits from European automotive customers.

Export Markets: As a secondary supplier, products are exported to Europe through Tier 1 suppliers.

13. Yonggu Hardware Factory, Xiaolan Town, Zhongshan

Core Strengths: A comprehensive manufacturer of traditional hardware products with strong cost advantages, ideal for standard parts and bulk purchases.

Technical Capability: Skilled in raw material optimization and layout, with exceptional cost control. Equipped with complete electroplating and spraying lines.

Main Products: Locks, hinges, slides, bathroom hardware accessories.

Factory Overview: Located in China’s hardware manufacturing base Xiaolan Town with a highly developed industrial chain.

Export Markets: Products distributed globally through major hardware distributors serving the DIY market.

14. Shenyang Northern Electromechanical Manufacturing Co., Ltd.

Core Strengths: Specializes in large and thick plate stamping parts for heavy machinery, power, and rail transit industries.

Technical Capability: Equipped with thousand-ton-level presses and capable of large mold machining and maintenance.

Main Products: Transformer cores, high-voltage switchgear enclosures, rail transit cabinets.

Factory Overview: A restructured state-owned enterprise with solid heavy equipment foundations, covering 35,000 m².

Export Markets: Mainly exports to CIS countries and India.

15. Chengdu Southwest Precision Parts Factory

Core Strengths: A representative enterprise in Southwest China with strong flexibility and fast service response.

Technical Capability: Provides full process capability from stamping to electroplating and powder coating, offering one-stop service for clients.

Main Products: Motorcycle parts, general machinery parts, customized sheet metal components.

Factory Overview: Covers 16,000 m² with a flat management structure and efficient decision-making.

Export Markets: Mainly serves domestic vehicle plants’ bases in Southeast Asia and directly exports to Southeast Asian markets.

FAQS

1. How do I choose the right stamping parts supplier for my project?

Choose a supplier based on your specific needs such as material type, part precision, production volume, and quality certification. Always check their equipment capability, sample quality, and experience in your industry.

2. What materials are commonly used in metal stamping?

Common materials include stainless steel (304, 316), carbon steel, aluminum, brass, and copper. The best choice depends on your part’s strength, corrosion resistance, and conductivity requirements.

3. What’s the typical tolerance level for precision stamping parts?

For high precision applications such as electronics or automotive components, tolerances can reach ±0.01mm or even tighter. Always confirm achievable tolerance with your supplier during the design stage.

4. How can I verify a stamping supplier’s quality capability?

Ask for IATF 16949, ISO 9001, or similar certifications, and request sample testing reports or in house inspection data. Factory audits and on site visits are also effective ways to confirm process control.

5. Do suppliers accept custom stamping orders or small batches?

Yes. Many professional stamping manufacturers, including FastenMetal LTD, support custom designs and small batch production, especially for specialized or prototype projects.

Conclusion:

These 15 suppliers each have their own strengths, covering the full spectrum of stamping technology from micron level precision components to ton scale structural parts. The key to successful sourcing lies in accurate matching: aligning your product’s technical requirements, quality standards, and order volume with the supplier’s area of expertise. It is recommended to conduct in depth sample verification and factory audits after the initial screening, as these steps form the foundation for building a long term and stable partnership.