Hex flange bolts are a popular type of fastener widely used in automotive, construction, machinery, and industrial applications. Known for their strength, ease of installation, and integrated flange design, these bolts combine the functions of a bolt and a washer, making them highly efficient in securing components. This guide will help you understand what hex flange bolts are, their advantages, applications, and material considerations.

What Are Hex Flange Bolts?

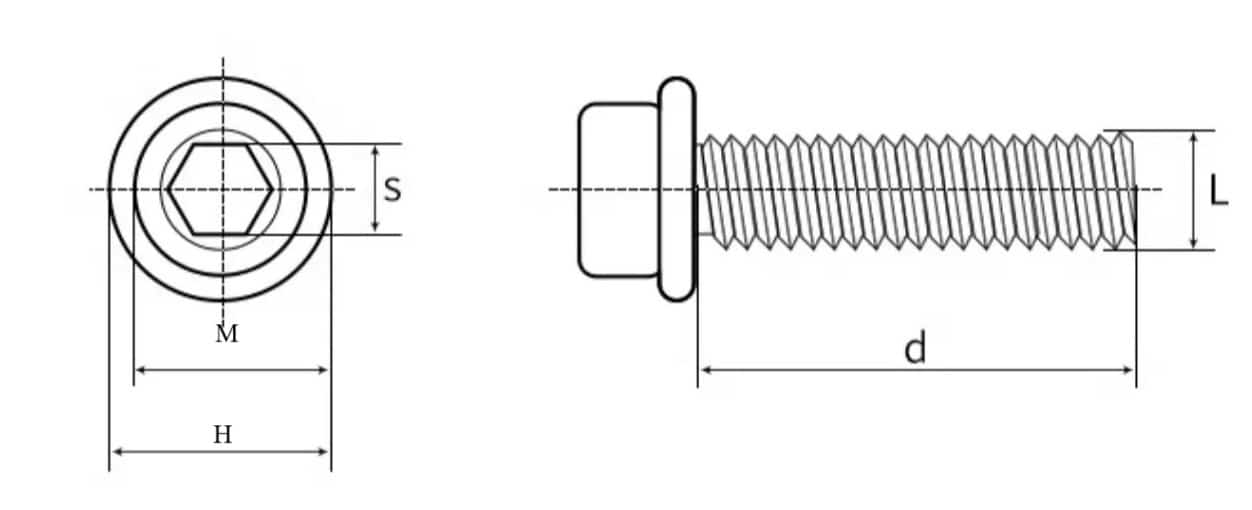

A hex flange bolt is a bolt with a hexagonal head and an integrated flange (a wide circular base) beneath the head. The flange acts like a built-in washer, distributing the load over a larger area and reducing the risk of damage to the material being fastened. This design minimizes the need for additional washers, saving time and simplifying assembly.The bolts are typically fully or partially threaded and come in various sizes, grades, and materials to suit different applications.

Advantages of Hex Flange Bolts

1.Load Distribution: The integrated flange spreads the load over a larger surface, reducing material stress and increasing joint strength.

2.Ease of Installation: With no separate washer needed, installation is faster and simpler.

3.Vibration Resistance: The flange helps prevent loosening in high-vibration environments, making it ideal for automotive and machinery applications.

4.Corrosion Resistance: Available in materials such as stainless steel, carbon steel with protective finishes, and alloy steel, hex flange bolts can withstand harsh environments.

5.High Strength: Especially in alloy and high grade steel, these bolts provide excellent tensile strength for heavy duty applications.

Common Materials and Finishes

Hex flange bolts are manufactured from a variety of materials, each selected to meet specific project requirements, environmental conditions, and mechanical performance needs. Understanding the material options can help ensure the right balance between strength, durability, and corrosion resistance.

1. Carbon Steel:

Carbon steel is one of the most commonly used materials for hex flange bolts due to its excellent strength-to-cost ratio. It provides sufficient mechanical strength for most industrial and construction applications. To improve corrosion resistance and extend service life, carbon steel bolts are often coated with protective finishes such as zinc plating, black oxide, or phosphate coating. These coatings not only prevent rust but also enhance the bolt’s appearance and reduce friction during installation. Carbon steel bolts are widely used in machinery, structural assemblies, and general-purpose fastening.

2. Stainless Steel:

Stainless steel bolts are highly valued for their superior corrosion resistance, making them ideal for outdoor, marine, or chemically aggressive environments. Common stainless steel grades used for hex flange bolts include 304, which offers good corrosion resistance for general outdoor applications, and 316, which provides enhanced resistance against chloride, saltwater, and other corrosive agents. Stainless steel bolts are slightly softer than high strength alloy steels but are preferred in applications where long term resistance to rust and chemical attack is critical, such as in marine equipment, food processing, and chemical plants.

3. Alloy Steel:

Alloy steel hex flange bolts are engineered for high strength and heavy duty applications. By adding elements such as chromium, molybdenum, or nickel, these bolts achieve superior tensile strength, toughness, and fatigue resistance. Alloy steel bolts are often heat-treated to further enhance mechanical properties, making them ideal for automotive assemblies, heavy machinery, and structural components where high load-bearing capacity is required. Because alloy steel can be more susceptible to corrosion, it is usually finished with coatings such as zinc plating, black oxide, or specialized anti-corrosion treatments to increase durability.

Finishes:

Beyond the base material, the finish or coating of a hex flange bolt plays a crucial role in extending service life, improving aesthetics, and reducing friction during installation. Common finishes include zinc plating for moderate corrosion protection, hot-dip galvanizing for long term outdoor exposure, black oxide for industrial environments, and specialty coatings for extreme chemical or marine conditions. Selecting the right combination of material and finish ensures that the bolt will perform reliably under the specific environmental and mechanical demands of the project.

Flange Hex Bolts Quality Standards

Flange hex bolt quality standards is crucial for ensuring safety, reliability, and compliance across various industries. Whether following European (EN), American (ANSI/ASME/ASTM), or international (ISO) standards, selecting the correct material, grade, size, and finish guarantees optimal performance in demanding applications. For projects that require precision, high strength, or custom specifications, partnering with an experienced manufacturer ensures that your flange hex bolts meet the necessary standards while providing long-term durability and reliability.

| Region | Main Standard Number / Series | Core Focus / Scope | Key Standard Examples / Notes |

|---|---|---|---|

| Europe (EN) | EN 1515 series | Selection and material classification of bolts, especially for equipment subject to the Pressure Equipment Directive (PED 2014/68/EU) | EN 1515-2: Classification of steel flange bolts by PN designationEN 1515-3: Classification of steel flange bolts by gradeEN 1515-4: Bolt selection guide for equipment under PEDEN 1092: Specifies flange dimensions, tolerances, pressure-temperature ratings; serves as the basis for selecting matching bolts |

| USA (ANSI/ASME/ASTM) | ASTM standards (e.g., A307, A325, A490) | Mechanical properties of bolt materials (strength, hardness, etc.) and grading requirements | ASTM A307: Low to medium strength boltsASTM A325 / A490: High strength structural bolts ASME B18.2.1, ASME B16.5: Bolt dimensions, specifications, and pipe flange/pipe fitting sizes & pressure ratings ASTM F704: Guidance for bolt length selection for flange connections |

| International (ISO) | ISO 4162, ISO 15071, etc. | Flange bolt product dimensions, tolerances, and performance grades | These are international product standards commonly cross-referenced or equivalently adopted alongside European and American standards |

Typical Applications

Hex flange bolts are extremely versatile and are used in industries that require secure and reliable fastening:

Automotive: Engine assemblies, chassis components, and suspension systems.

Construction: Steel structures, machinery, and heavy equipment assembly.

Industrial Equipment: Conveyor systems, motors, and mechanical assemblies.

Electronics and Appliances: Fastening components where a secure, vibration-resistant connection is required.

Their built-in flange and highstrength options make them particularly suitable for applications where both load distribution and durability are critical.

Conclusion

Hex flange bolts are a reliable, versatile, and efficient fastening solution suitable for a wide range of industries. Their integrated flange design, high strength, and vibration resistance make them an excellent choice for projects that demand durability and secure fastening. Whether for automotive, construction, or industrial machinery, choosing the right material, grade, and finish ensures the longevity and performance of your assembly. For projects requiring high quality flange bolts, Fastenmetal is an experienced flange bolt manufacturer provides reliable solutions according to your specific needs.