In high temperature and highly corrosive environments, the durability of refractory linings directly determines the reliability and maintenance costs of industrial equipment.Stainless steel hexmesh, also known as refractory hex metal, plays a important role in protecting these linings. Far beyond a simple metal mesh, it’s a highly engineered structure that integrates material science, mechanical design, and practical engineering. At Fastenmetal LTD, we specialize in custom manufacturing of high temperature metal components and anchoring systems. This article explores stainless steel hexmesh in depth.from its materials and mechanical design to industrial applications and selection guidelines.

1. Structural Parameters Overview

| Parameter | Common Range | Engineering Function |

|---|---|---|

| Mesh Pitch | 2–6 cm | Determines refractory bonding strength and castability |

| Sheet Thickness | 1–3 mm | Influences rigidity and wear resistance |

| Mesh Depth (Rib Height) | 1–2.5 cm | Matches refractory lining thickness, providing strong 3D anchorage |

Typical Applications:

Stainless steel hexmesh is widely used for furnace linings, boiler interiors, ducts, petrochemical reactors, waste incinerators, and other high temperature, abrasion resistant areas.After being spot welded to the steel shell, refractory materials are cast inside the mesh to form a reinforced, integrated protection layer,greatly extending service life.

2. Material: More Than Just “Stainless Steel”

The performance of hexmesh begins with its material. Each stainless steel grade offers distinct advantages depending on the working environment:

304 / 304L – Economical universal grade

Resistant to oxidation up to ~800°C. Commonly used in general chemical equipment and flue gas ducts.

321 – Intergranular corrosion–resistant type

Titanium-stabilized for better resistance to sensitization (450–850°C). Ideal for welding zones and fluctuating thermal conditions.

316 / 316L – Pitting corrosion champion

Molybdenum addition enhances resistance to chlorides and reducing acids—perfect for coastal plants and halogen-containing chemical processes.

310S – High temperature oxidation expert

High chromium and nickel content ensures outstanding oxidation resistance up to 1150°C. Common in FCCU regenerators and boiler burners.

314 / 330 – Special high-temperature alloys

With even higher Ni and Cr contents, these alloys excel in extreme furnace environments such as ethylene cracking or reforming units.

Fastenmetal Tip:

Failure of hexmesh often starts at the edges of its V shapd ribs due to combined thermal, mechanical, and chemical stresses. Accurate material selection based on temperature, atmosphere, and medium is the foundation of reliable lining performance.

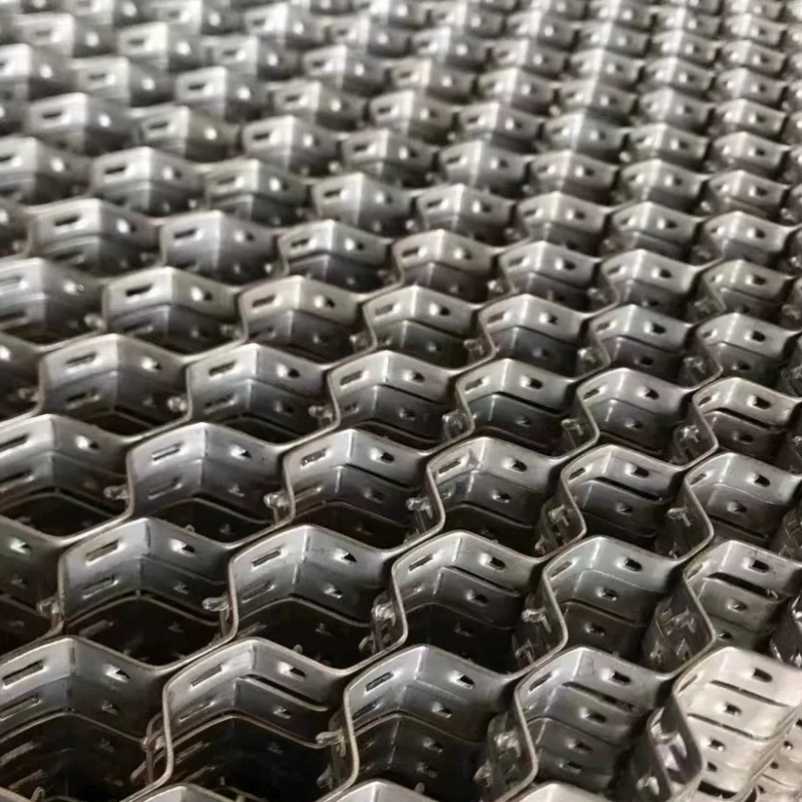

3. Structural Mechanics: The Engineering Logic of the V Shape Design

The unique V shape rib structure of stainless steel hexmesh isn’t just aesthetic.It’s a result of deep mechanical engineering insight.

Mechanical Interlocking:

When refractory castables cure within the mesh, a three dimensional mechanical bond forms, far stronger than a simple surface adhesion.

Stress Distribution:

The V shape ribs help evenly distribute thermal and shrinkage stress, preventing crack propagation in the lining.

Impact & Wear Resistance:

Each rib acts as a micro “reinforcing fin,” redirecting impact energy away from the surface and dissipating it laterally which enhancing abrasion resistance.

Thermal Flexibility:

Unlike solid steel plates, hexmesh offers flexibility to accommodate thermal expansion and contraction of the equipment shell, preventing spalling or delamination.

4. What Industries use Hex Metal?

Petrochemical Industry (FCCU Regenerators)

Challenge: 700–900°C high temperatures, high-velocity catalyst erosion, and corrosive CO/CO₂/SOx gases.

Solution: Use 310S stainless steel hexmesh, precisely customized mesh size and wire thickness based on catalyst flow rate and lining thickness. Welded firmly to anchor studs to form a rigid skeleton.

Power Generation (CFB Boilers)

Challenge: Severe wear from circulating ash and frequent temperature cycles.

Solution: Combine hexmesh with ultra-wear-resistant castables to form an “armor-type” lining that withstands both abrasion and thermal shock.

Waste Incineration Plants

Challenge: Highly corrosive gases (HCl, SOx) and heavy metal vapors at high temperature cause rapid metal degradation.

Solution: Employ nickel alloy hexmesh or pair with SiC refractory bricks to resist both corrosion and erosion simultaneously.

5. How to Select and install?

The Key Selection Parameters include:

Mesh Pitch (TL): Smaller pitches offer stronger grip but lower castable flow; larger pitches improve flow but reduce bonding area.

Wire Thickness (SW): Determines mesh strength—thicker wires for high stress or abrasive zones.

Mesh Depth (ST): Should match refractory lining thickness for structural integrity.

Conclusion

Stainless steel hexmesh represents the perfect synergy between material science, mechanical engineering, and industrial practicality. From selecting the right alloy for specific environments to leveraging the V shape design for superior anchorage and wear resistance.Every detail contributes to safer and longer-lasting equipment operation.

Fastenmetal LTD provides fully customized hexmesh solutions, including Various materials (304, 310S, 316, 330, nickel alloys);Adjustable mesh pitch, thickness, and rib depth; Complete anchor studs and refractory lining system support. With our expertise, your refractory lining becomes a true industrial armor.built for performance, reliability, and longevity.