- +86 18015401692

- sales@fastenmetal.com

Trusted by Over 1000 Customers All Over the World

Flange Bolts

Flanged Bolts features hexagonal head with integrated flange plate. FastenMetal is one of the best flanged bolts manufacturers in China. Flanged bolts are widely used to Automotive and Machinery, Construction,Industrial Equipment ,etc. We offer various types of flanged bolts with a range of sizes and materials. We also produce non-standard flanged bolts according to customer drawings.

- 2 Self-owned Factories

- ISO 9001:2015 certificated

- Hundreds of Suppliers

Gallery of Flange Bolts

-

Dacromet Hex Flange Bolts

Add to cartDacro hex flange bolts are specialized fasteners featuring a hexagonal head and a built-in flange that provides a larger bearing surface. Coated with Dacromet will enhance corrosion-resistant,durability and longevity. These bolts are commonly used in various applications, including automotive and construction, where strong, secure connections are needed. Their design allows for easier installation and helps distribute load evenly. For quotes,inquiries,or custom bolts request, please feel free to click the button”get a free quote”.Material: Stainless Steel 304,316, brass,Carbon Steel

Standard:DIN

Finish: Dacromet

Size:M6-M80

Strength Grade:Grade8.9,10.8,12.8

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

Socket Countersunk Flange Bolts

Add to cartSocket countersunk flange bolts are fasteners with a cylindrical head designed to sit flush with the surface of the material they’re fastened to. They feature a hexagonal socket drive for easy installation using an Allen wrench. The flange provides additional surface area, distributing the load and enhancing stability. These bolts are commonly used in applications where a clean, flat finish is required, making them ideal for machinery, automotive parts, and furniture assembly.For quotes,inquiries,or custom bolts request, please feel free to click the button”get a free quote”.

Material: Stainless Steel 304,316, brass

Standard:DIN

Finish: As finished

Size:M6-M80

Strength Grade:Grade8.9,10.8.12.8

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

Stainless Steel Hex Flange bolt

Add to cartA stainless steel hex flange bolt is a fastener with a hexagonal head and a built-in flange that acts as a washer. It’s designed for use in heavy-duty applications, providing a secure grip and distributing load evenly. The stainless steel material offers excellent corrosion resistance, making it ideal for outdoor and marine environments. These bolts are commonly used in construction, automotive, and machinery assembly. For quotes,inquiries,or custom bolts request, please feel free to click the button”get a free quote”.

Material: Stainless Steel 304,316, brass

Standard:DIN

Finish: As finished

Size:M6-M80

Strength Grade:Grade8.9,10.8

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

Still not finding what you’re looking for? For fasteners that are unavailable as standard products, or for very specific requirements, we can manufacture custom fasteners and fixings exactly to your specifications or drawings.

About Flange Bolts

What is flange bolts?

Flange bolt is a type of bolt used for connecting flanges. It is typically composed of three parts: a hexagonal head, a flange, and a threaded rod. Like flange nuts, it also have a flange plate.The hexagonal head and the flange are fixed together, while the rod is a cylindrical part with external threads. Flange bolts are generally used together with nuts.

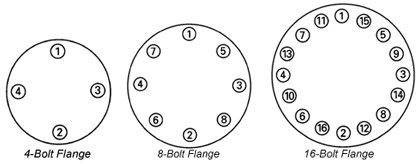

How to fasten flange bolts correctly?

1.Before installing the flange, the flange bolts must be placed in the flange holes to ensure that each hole has a bolt installed.

2.The flange bolts must be rotated backward under the flange, and then the flange should be placed on the flange bolts.

3.Before installing the flange nuts, the flange must be rotated 90 degrees to ensure all the flange holes are aligned in a straight line.

4.Before tightening the flange nuts, they must be tightened in a crisscross pattern, starting by tightening the bolt in hole 1, then tightening the corresponding bolt in hole 4, followed by tightening the bolts in holes 2 and 3.

5.Repeat the above steps until all the flange nuts are tightened to the standard torque.

Notice to install flange bolts

1.Bolts and nuts of the same material and strength grade as the flange should be used.

2.The bolt length should be slightly longer than the combined thickness of the flange and gasket to ensure proper fastening and sealing.

3.The nuts should only be tightened after the flange bolts are correctly installed to ensure the flange is accurately positioned.

4.A torque wrench should be used to tighten the flange nuts, following the specified torque values and tightening them one by one.

5.Before tightening the flange nuts, the surface of the flange and the coating (black or blue) on the bolts and nuts should be cleaned to avoid misjudging the tightness.