FastenMetal Foundation Bolts Solution for Longfeng

Heavy Industrial New Factory

Fastenmetal specializes in the design and manufacture of high strength foundation anchor bolts engineered to meet the stringent demands of heavy industrial and critical construction projects. Beyond standard anchor forms such as the basic J-Type, L-Type, and U-Type bolts,we excel in providing custom welded foundation anchor systems specifically according to individual customer project requirements.

Our material capabilities include stainless steel 304,316, high strength Q345 ,Q355 and so on. All our fasteners are strictly quality checked and ensure meet international ISO and ASTM standards.

Project Case : High Performance Seismic Resistant Anchor Bolt System Solution for Longfeng Heavy Industry's New Production Base

Client Name: Longfeng Heavy Industry (A large-scale modern heavy equipment manufacturing facility)

Industry: Large Scale Industrial Construction / Heavy Equipment Manufacturing

Project Duration: August 15, 2023 – October 10, 2023

I. Project Background and Challenges

Longfeng Heavy Industry’s new production base, representing a total investment of 5 billion CNY, required the installation of several heavy gantry cranes and precision CNC machine tools within its core workshop (36m span, 420m length). The base is located in a seismically active belt in Southwest China, demanding extremely high anti-seismic performance for the factory structure. Therefore, the foundation bolts is the “lifeline” connecting equipment to the foundation had to meet critical challenges concerning positioning accuracy, structural strength, and seismic fatigue resistance.

Client’s Explicit Requirements:

Material: High strength Q355 steel.

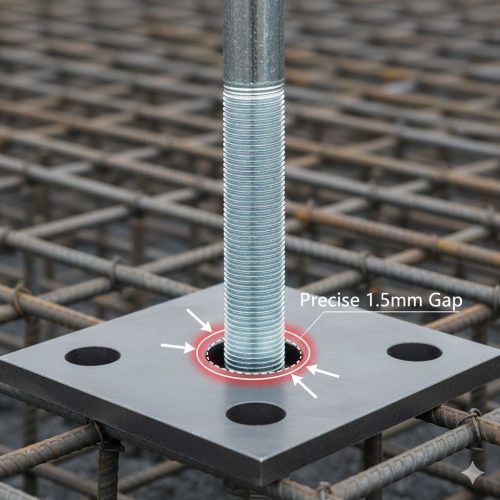

Positioning Accuracy: Provision of customized positioning templates (hole diameter 1-5mm larger than the bolt) to strictly ensure the verticality deviation of any single anchor bolt is controlled within 1.5mm.

Quality Standard: Far exceeding national standards, ensuring the long term safety of the factory structure throughout its design life.

II. Our Customized Solution

We established a dedicated technical task force to thoroughly analyze the client’s needs and site conditions, delivering a comprehensive, beyond-standard solution.

1. Core Technology: Anchor Plate and Rod Seismic Strengthening System

Addressing the frequent seismic activity, we rejected simple single rod bolts and innovatively adopted an integrated “Anchor Plate + Rod” design.

Mechanism: The thickened anchor plate (thickness customized based on stress calculations) forms a larger contact surface with the concrete foundation, uniformly dispersing the massive dynamic loads (such as seismic forces) transmitted by the equipment. The rod is joined to the plate using a full penetration groove weld, ensuring smooth and uninterrupted load transfer.

Supporting Data: Third-party laboratory simulation testing showed that this combined system significantly improved fatigue resistance by over 30% compared to traditional straight rod anchor bolts, effectively acting as a “seismic armor” for the entire factory structure.

2. Precision Manufacturing and Dual Accuracy Control

To ensure the precise positioning of hundreds of bolts, we implemented dual level accuracy control:

Component Level Accuracy: All anchor rods were fine machined using CNC equipment, guaranteeing thread precision and rod straightness.

System Level Accuracy: We customized 5mm thickness Q355 positioning templates for the client. The holes in the templates were pre-cut by CNC plasma, ensuring the hole diameter was exactly 3mm larger than the bolt diameter (the optimum value within the client’s 1-5mm range). This template served as a “jig” on site, fixing the relative positions of multiple bolts simultaneously and fundamentally ensuring the overall installation accuracy of the bolt group.

3.Ultra Long Life Anti-Corrosion Treatment

To counter potential humidity in the plant area, we applied hot-dip galvanizing (HDG) treatment, voluntarily increasing the coating thickness from the conventional 50-70mu to an average of 85mu. This significantly extended the bolt’s corrosion resistance life within the concrete, matching the structural design life of the building.

III. Project Execution Structure and Results

|

Project Metric

|

Client Requirement

|

Our Achieved Results

|

Quantifiable Benefit

|

|---|---|---|---|

|

Final Accuracy

|

Verticality < 1.5mm

|

Average verticality deviation <1.0mm, 100% pass rate

|

Paved the way for "first-time crane installation," saving significant adjustment time.

|

|

Final Delivery

|

Contractual 40 days

|

Completed in 35 days (5 days ahead of schedule)

|

Gained valuable time for the client's critical path construction schedule.

|

|

Product Quality

|

National standard 100% passing rate

|

100% ex-factory inspection passing rate, zero site returns

|

Avoided project delays and rework costs caused by quality issues.

|

|

Cost Savings

|

-

|

Saved the client approx. 15% in comprehensive costs through process optimization and logistics

|

Savings realized not only in the product itself but also in indirect costs from reduced construction time and labor.

|

|

Client Satisfaction

|

-

|

Project Score: 98/100

|

Highly praised by the client for quality, delivery, and service response.

|

IV. Main Process Improvements

Welding Process Optimization: Adopted CO₂ gas-shielded welding and subjected welders to specialized certification to ensure the anchor plate to rod connection welds were full, free defect, and verified by ultrasonic flaw detection spot checks.

Galvanizing Process Control: Increased pickling activation time control before hot-dip galvanizing, and used centrifugal spinning after dipping. This ensured a uniform coating thickness on the threads, preventing “thread seizing” and facilitating easy nut tightening.

Digital Management: Each bolt set was equipped with a unique QR code, allowing instant access to specifications, production batch, and inspection reports, enabling full lifecycle quality traceability.

V. Client Testimonial

Custom Your Foundation Bolts Today!

At Fastenmetal, we specialize exclusively in the design and manufacture high strength foundation anchor bolt systems. These essential fasteners are the critical link between massive structures and their concrete foundations in demanding construction, heavy industrial, and energy projects. We provide a complete range of standard and custom foundation bolt solutions, manufactured with high quality materials and stringent quality control to ensure maximum strength, durability, and long term reliability.

Core Offerings & Certification

Foundation Bolt Range: We offer a wide range of anchor types, including standard J-Type, L-Type, U-Type, Eye-Type, and Custom Welded Anchor Plate Systems (e.g., for enhanced seismic resistance).

Material Capabilities: Supported materials include stainless steel (304, 316), high strength structural steels (Q345, Q355), and other grades tailored to specific load and corrosion requirements.

Customization: We specialize in supporting special foundation bolts and customised designs to meet unique project specifications, dimensional tolerances, and structural needs.

Order Flexibility: Minimum Order Quantity (MOQ 1000 pcs) for standard items; special material, custom-welded systems, or extra large sizes are discussed and quoted separately.

Global Export: Reliable manufacturing capacity with competitive pricing and extensive global export experience ensures timely delivery to your construction site worldwide.