In modern engineering, whether it’s power transmission lines, communication towers, or solar energy installations, heavy duty pole clamps play a important role in ensuring structural stability. Although they may appear as simple fasteners, these components are responsible for connecting, securing, and supporting various structures and equipment. This article provides a comprehensive overview of heavy duty pole clamps, including their features, applications, and selection guidelines.

What Are Heavy Duty Pole Clamps?

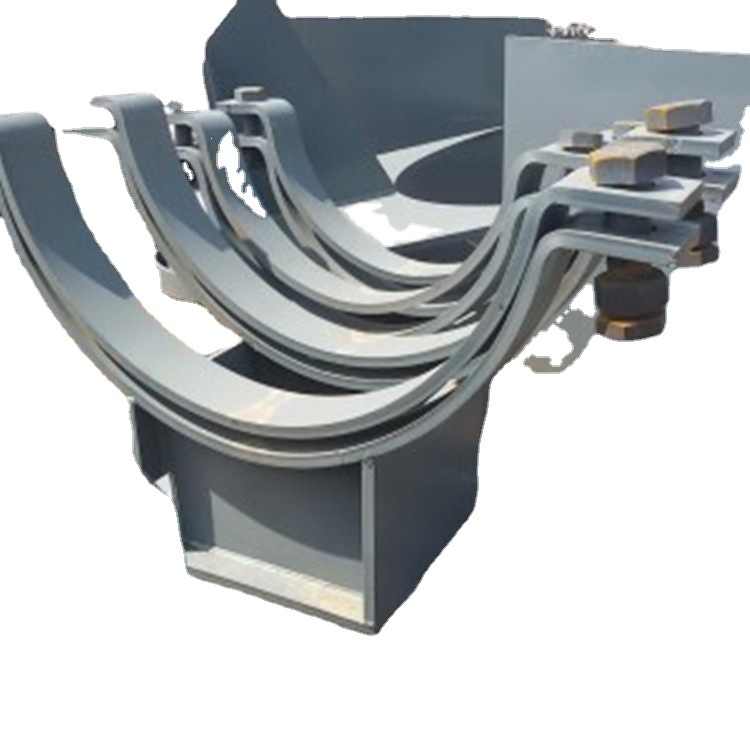

Heavy duty pole clamps are mechanical fasteners used to secure poles or columns to supporting structures. Typically, they consist of two interlocking metal halves that are tightened around a pole using high-strength bolts. The core design ensures a secure fit on poles or towers, providing a reliable mounting point for various equipment. A standard pole clamp assembly includes clamp plates, wing plates, bracing plates, bolts, and inner liners. This configuration allows the clamp to withstand substantial tensile and shear forces, ensuring stability even in extreme environmental conditions.

Main Advantages of Heavy Duty Pole Clamps

1. Exceptional Load Bearing Capacity

Heavy duty pole clamps are engineered for high strength and stability. Their primary performance metric is the ultimate load (kN), which can be customized to meet the specific requirements of different projects.

2. Superior Corrosion Resistance

Clamps are often hot-dip galvanized: surface rust is removed through acid pickling, then dipped in molten zinc at around 450°C, and finally cooled with a special agent. This process produces a durable, shiny surface that offers excellent resistance to oxidation, acid, alkali, and wear, significantly extending the service life of the clamp.

3. Wide Applicability

Clamp specifications can be customized to suit different application scenarios, including variations in size, shape, and material. This flexibility allows heavy duty pole clamps to meet the diverse needs of multiple engineering projects.

Typical Applications

1. Power Engineering

In power engineering, heavy duty clamps are used to secure utility poles, tower crossarms, insulators, and cables, ensuring the stability of transmission lines.

High voltage transmission lines: Flat iron clamps can fix crossarms to towers, preventing displacement due to wind or external forces, ensuring uninterrupted power transmission.

Substation installations: Clamps secure transformers, distribution cabinets, and cable trays, maintaining orderly cable layout and preventing operational failures caused by vibrations or external impacts.

2. Telecommunications

In telecom tower construction, clamps secure antennas, feeders, and optical cables on poles and towers.

Antenna installation: Properly clamped antennas resist tilting from wind, ensuring reliable signal coverage.

Overhead fiber optic lines: Clamps fix cables evenly along poles or towers, preventing sagging or breakage.

3. Solar Energy Installations

In solar projects, photovoltaic (PV) mounting pole clamps secure vertical poles and diagonal braces.

Hot dip galvanized clamps provide long-term durability and reduce material costs.

They can withstand the weight of solar panels and environmental loads, such as wind.

Commonly used in agro-photovoltaic or fishery-integrated PV systems, clamps evenly distribute forces to the pole, reducing tensile and lateral stress on the upper sections of the structure, and improving overall support performance.

4. Other Applications

Heavy duty pole clamps are also widely used in:

Municipal and traffic projects: fixing streetlights, traffic signal poles

Construction and steel structures: connecting and securing steel beams and columns

Industrial and manufacturing facilities

Agriculture and water management projects

Essentially, they are applicable in any project requiring secure fixing, connection, and support.

How to Select the Right Heavy Duty Pole Clamp

1. Identify the Application and Requirements

Power engineering: Focus on ultimate load and corrosion resistance.

Telecommunications: Emphasize vibration resistance and durability.

Solar installations: Prioritize wind load resistance and long-term stability.

2. Determine Clamp Size

Clamp diameter is primarily determined by pole diameter. A practical calculation can be:

D₁ = L₁ / 75 + d_min

Where:

-

D₁ = clamp diameter at a specific height

-

L₁ = distance from the pole top

-

d_min = minimum pole diameter at the top

Example: For a φ190mm × 15m pole, to install a clamp 1.2m from the top:

D₁ = 1200 / 75 + 190 = 206 mm

3. Material Selection

Standard material: Q235 flat steel, which provides adequate strength and ductility.

High corrosion environments: Consider stainless steel (304 or 201).

4. Surface Finish

Hot-dip galvanization is preferred for excellent corrosion protection.

Zinc coating thickness is an important indicator of clamp quality.

Installation and Maintenance

Installation Guidelines

Clean mounting surface: Remove debris or protrusions for full contact.

Symmetrical bolt tightening: Tighten bolts alternately to ensure uniform load distribution.

Torque control: Follow recommended torque to avoid over-tightening or under-tightening.

Regular inspection: Check clamps periodically for tightness and surface condition.

Maintenance Recommendations

Inspect clamps for corrosion or damage regularly.

Check bolts for loosening and re-tighten if necessary.

In corrosive environments, consider additional protective measures or reduce inspection intervals.

Conclusion

Heavy duty pole clamps are foundational components in power, telecommunications, and solar installations. Selecting the right clamp impacts not only the initial construction quality but also the long term stability and safety of the entire structure.

Whether securing transmission lines across vast distances, supporting communication networks in urban and rural areas, or anchoring solar energy systems, Pipe clamps play an indispensable role. Proper selection, installation, and maintenance are essential responsibilities for every engineering professional. For more information or personalized selection guidance, please contact our technical team for expert solutions.