Titanium bolts are becoming very common in many industries today. People choose them because they are very strong, very light, and very resistant to rust. Many factories and engineers want bolts that can work in high heat, high pressure, and outdoor environments. Stainless steel bolts can work well, but titanium bolts offer better strength to weight performance. Because of this, many industries are slowly replacing old steel bolts with titanium bolts.

This blog explains what titanium bolts are, how they are used, how strong they are, how they compare to stainless steel bolts, the weight difference, and how they are made. The language is simple, and each section moves in a clear way so you can understand every point easily.

1. What Are Titanium Bolts

Titanium bolts are fasteners made from titanium metal. Titanium is known for its strength and very low weight. Titanium is also known for its very high resistance to corrosion. Many metals can rust in water or chemicals, but titanium stays stable. Titanium also works well in high temperatures. Because of these basic advantages, bolts made from titanium can handle heavy stress without breaking or bending.

Titanium itself is a natural metal. It is found in minerals and rocks. The metal must be extracted in a special process that is more complex than steel production, so the material costs more. But even though the cost is higher, the benefits often make the investment worth it, especially in industries where safety and performance are very important.

Titanium bolts usually come in different grades. The most common grade is Grade 5, also called Ti-6Al-4V. This grade mixes titanium with aluminum and vanadium to become even stronger. Pure titanium (Grade 2) is also used in some cases, especially in chemical and medical industries where corrosion resistance is more important than extreme strength.

Many people pick titanium bolts because the metal has one of the best strength-to-weight ratios in the world. This means titanium can be very strong even when the bolt is very light. Industries like aerospace and motorsport look for materials like this because every gram of weight affects speed and performance.

2. Titanium Bolts Applications

Titanium bolts are used in many different industries. Engineers choose them when they want strong bolts that do not add too much weight. Below are some places where titanium bolts are commonly used.

Aerospace

Airplanes and spacecraft need to reduce weight. When weight goes down, fuel use also goes down. This means the aircraft can travel longer and perform better. Because titanium bolts are strong and light, they are used in wings, engines, landing gear, and many internal structures.

Automotive and Motorsport

Racing cars need the best performance. Every part must be light but strong. Many race teams replace steel bolts with titanium bolts to reduce total vehicle weight. This helps the car accelerate faster and handle better. Motorcycles and high-end street cars also use titanium bolts for wheels, brakes, and suspension systems.

Bicycle Industry

High performance bicycles use titanium bolts to reduce weight in handlebars, seat posts, brakes, and frames. Cyclists want very light bikes, and titanium helps reduce grams in many parts without losing safety.

Marine Industry

Saltwater can damage many types of metal. But titanium handles saltwater very well. Ships, submarines, and offshore equipment often use titanium bolts because they do not rust even when they stay in seawater for many years.

Chemical Plants

Chemical factories use machines that handle acids, bases, and corrosive liquids. Stainless steel can sometimes react with these chemicals. Titanium bolts can stay stable even in strong chemical environments, so they are used in pumps, valves, and tanks.

Medical Field

Titanium is safe for the human body. It does not react with body fluids and tissues. Because of this, titanium bolts are used in medical implants, bone plates, and surgical tools.

Sports Equipment

High-end sports equipment such as climbing gear, tennis rackets, and camping equipment sometimes use titanium bolts for extra strength without the heavy feel.

These examples show that titanium bolts are used anywhere people need long-lasting performance, low weight, and high safety.

3. Titanium Bolts Strength Grade Compared with Stainless Steel

Titanium bolts are known for very high strength. Many people compare titanium bolts with common stainless steel bolts to decide which is best for their project.

Strength Levels

The most common titanium grade is Grade 5 (Ti-6Al-4V). This grade is extremely strong and is often stronger than stainless steel 304 and 316 bolts. Stainless steel bolts are strong, but they are not as strong as titanium when comparing the same weight.

A large advantage is that titanium keeps its strength at high temperatures. Stainless steel can lose strength when heat gets too high. Titanium stays stable and can keep working in hotter environments.

Corrosion Resistance

Stainless steel has good corrosion resistance, especially 316. But titanium is even better. Titanium forms a natural oxide layer that protects it from rust, acids, saltwater, and many chemicals. Stainless steel can still rust under extreme conditions, but titanium rarely does.

Strength-to-Weight Ratio

This is the key difference. Titanium bolts are much lighter than stainless steel bolts but still very strong. Stainless steel has good strength, but it becomes very heavy when used in large quantities. Titanium can give the same strength with much lower weight.

Cost

Titanium bolts cost more because titanium metal is harder to extract and process. But the performance benefits often make the cost worth it for critical applications.

4. Titanium Bolts Weight vs. Stainless Steel Bolts Weight

Weight is one of the biggest reasons why people choose titanium bolts. Titanium is around 40% lighter than stainless steel. For example, if a stainless steel bolt weighs 100 grams, a titanium bolt of the same size may weigh only about 60 grams.

This weight difference matters a lot when a machine or structure uses many bolts. When engineers replace every stainless steel bolt with a titanium bolt, the total weight can drop by several kilograms. In aerospace, one kilogram of weight reduction can save a large amount of fuel over a plane’s lifetime. In motorsport, a few hundred grams can change the performance of a car or motorcycle.

In bicycles, climbers’ gear, drones, robots, and many other industries, every gram matters. So titanium bolts give both strength and low weight at the same time. This is something stainless steel bolts cannot do as well.

5. How to Make Titanium Bolts

Titanium bolts are made through several steps. Making titanium bolts takes more time and skill than making regular steel bolts because titanium is harder to process. Below is a simple explanation of how titanium bolts are produced.

Step 1: Cutting the Raw Material

Titanium rods are cut into pieces. Each piece will become one bolt.

Step 2: Forging

The cut pieces are put into a forging machine. The machine presses them to form the bolt head. This can be done cold or hot, depending on the bolt size and grade.

Step 3: Forming the Threads

Next, the thread is created. It can be rolled or cut. Rolling is common because it makes the thread stronger.

Step 4: Heat Treatment

Titanium bolts are heat-treated to improve strength and hardness. Heat treatment also makes the bolt more stable during use.

Step 5: Cleaning

The bolts are then cleaned. Titanium can form small surface marks, so cleaning and polishing help improve appearance and remove impurities.

Step 6: Inspection

Every bolt is checked carefully. The inspector looks for small cracks, uneven surfaces, or size errors. Titanium bolts must meet strict quality standards, especially for aerospace and medical industries.

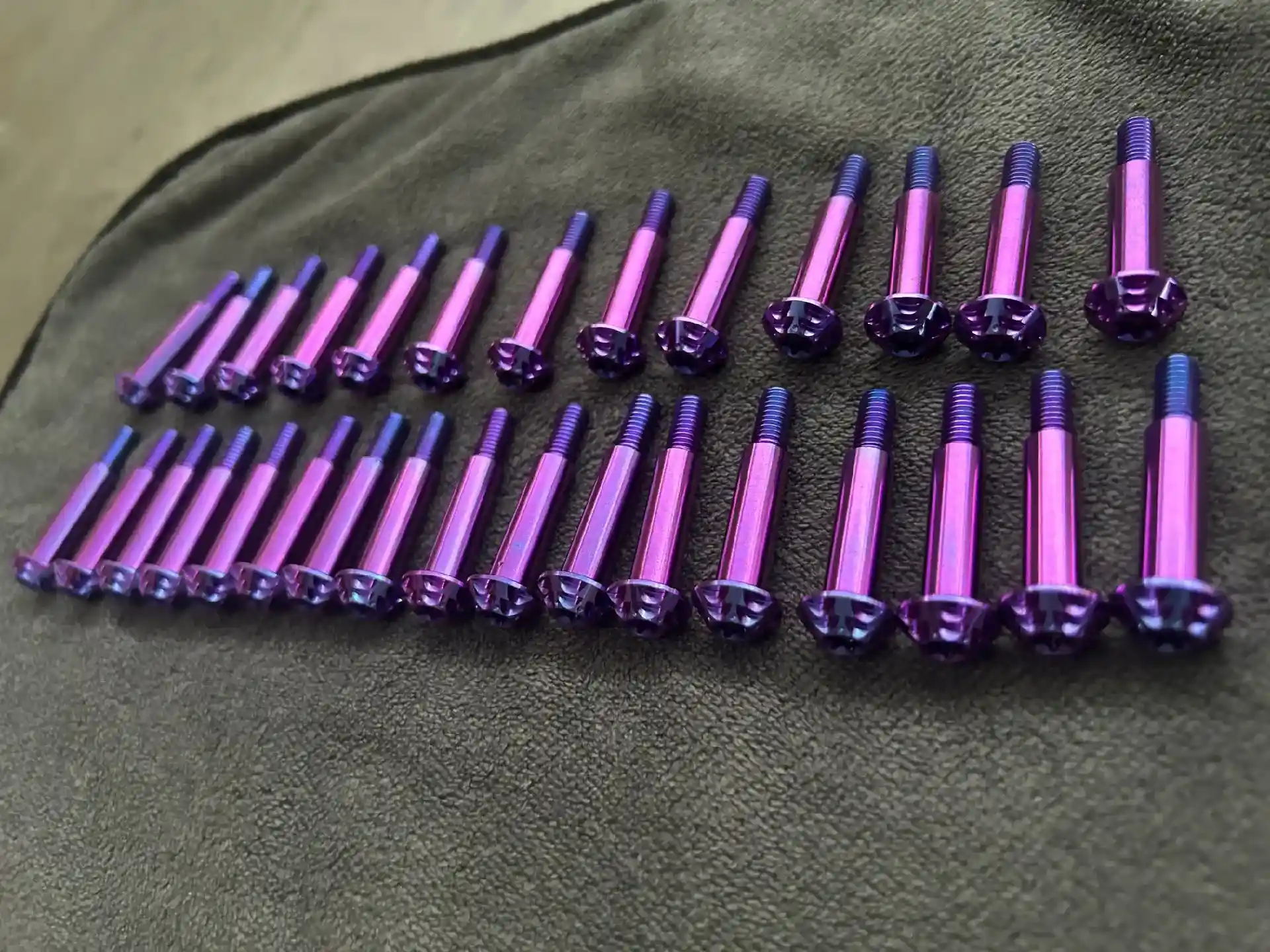

Step 7: Finishes

Some titanium bolts receive a finish. The finish can improve appearance or give extra protection.

Step 8: Packaging

Finally, the bolts are packed and prepared for shipping.

Conclusion

Titanium bolts give strong performance, low weight, and great resistance to corrosion. They work well in many industries because they stay strong in high heat, heavy load, and harsh environments. When people compare them with stainless steel bolts, titanium bolts offer better strength-to-weight results and longer service life. The cost is higher, but the value is also higher in projects that need safety and high performance. Because of this, more engineers and factories choose titanium bolts for advanced machines, vehicles, and equipment.