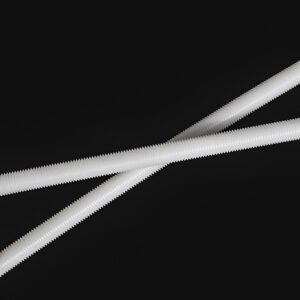

A nylon threaded rod is a rod made from high performance nylon (typically PA6 or PA66) that features continuous threading along its length. This allows the rod to accept nuts and connectors, making it suitable for joining components in both temporary and permanent assemblies.

Nylon threaded rods are available in a wide range of metric and imperial sizes, offering versatility for different industries from electrical installations to marine and industrial equipment.

Key Advantages of Nylon Threaded Rods

1. Lightweight and Easy to Handle

Nylon rods are up to seven times lighter than steel, making them easier to transport, cut, and install. Reduced weight can also lower structural load in assemblies where metal rods may be unnecessarily heavy.

2. Corrosion and Chemical Resistance

Nylon is naturally resistant to moisture, saltwater, oils, and most chemicals, making these rods ideal for outdoor, marine, and industrial environments where metal fasteners would corrode over time.

3. Electrical Insulation

Unlike metal fasteners, nylon is non-conductive, making it safe for applications in electrical panels, electronic enclosures, and grounding-sensitive equipment.

4. Sufficient Mechanical Strength

While not as strong as steel, nylon threaded rods provide excellent tensile strength and rigidity for non-structural load-bearing applications. Austenitic nylon (PA66) can withstand moderate mechanical forces, vibration, and thermal expansion.

5. Easy to Customize

Nylon rods can be cut, threaded, or machined on site, and paired with nylon nuts and washers to maintain full material compatibility.

Common Applications

Nylon threaded rods are particularly useful in situations where their unique properties outweigh the higher load capacity of metal:

Electrical and Electronics: Safe mounting in panels and insulated equipment.

Marine Environments: Corrosion resistance in boats, docks, and coastal installations.

HVAC and Construction: Lightweight fastening for ductwork or non-structural frameworks.

Industrial Equipment: Resistant to moisture, chemicals, and moderate mechanical loads.

Automotive and Aerospace: Applications where weight reduction and chemical resistance are critical.

Limitations to Consider

While versatile, nylon threaded rods have some limitations:

Lower Load Capacity: Not suitable for high structural loads.

Temperature Sensitivity: High heat may soften the material; suitable mostly for moderate temperatures.

Moisture Absorption: Nylon can absorb water over time, slightly altering dimensions and strength.

Understanding these limitations ensures safe and reliable use in the correct applications.

Practical Tips for Use

Always select the appropriate grade of nylon for your environmental conditions (PA66 for higher strength and temperature resistance).

Pair nylon rods with compatible nuts and washers to avoid material incompatibility.

Ensure correct sizing for load and span to prevent creep or deformation over time.

For marine or outdoor applications, consider UV-stabilized nylon for longer life.

Nylon threaded rods combine lightweight design, corrosion resistance, and electrical insulation to deliver reliable performance in a wide range of applications. Whether used in electrical assemblies, marine environments, HVAC systems, or industrial equipment, these rods provide a safe, durable, and cost-effective fastening solution. By choosing Fastenmetal nylon threaded rods, engineers and architects can ensure long lasting reliability, ease of installation, and superior performance, even in challenging environments.