- +86 18015401692

- sales@fastenmetal.com

Trusted by Over 1000 Customers All Over the World

Refractory Anchors

Refractory anchors are type of metal parts that fixing refractory material to the metal walls of kiln. There are many shapes of refractory anchors such as such as V-shaped, U-shaped, Y-shaped, mesh, π-shaped, etc. FastenMetal is one of the best refractory anchors manufacturers In China, We manufacture various types of refractory anchors. We also produce special refractory anchors according to customer drawings.

- 2 Self-owned Factories

- ISO 9001:2015 certificated

- Hundreds of Suppliers

Gallery of Refractory Anchors

-

Custom Refractory Anchor

Add to cartAt FastenMetal, we manufacture a wide range of refractory anchors designed to perform reliably in high-temperature and high-pressure applications.For custom non standard refractory anchors, please feel free to send us drawing to inquiry.We recoomend using various raw materials such as SS 310, SS 304, SS 316, Inconel 601, Inconel 625, Inconel 800, and RA 330。 Additionally, our refractory anchors made from SS 316 are renowned for their exceptional quality and performance. Our goal is to produce anchors that offer high tensile strength, corrosion resistance, and precise dimensional accuracy.

Material: :heat-resistant steel(1Cr18Ni9Ti) SUS321,304 Stainless Steel,310 Stainless Steel,316 Stainless Steel,Inconel,Carbon steel

Surface: As finished

Size: As per drawing

Brand: Unbranded/Generic

Application: Industrial Furnaces and Kilns,Petrochemical and Chemical Plants,Power Generation,Heat Treatment Facilities,Cement and Lime Kiln

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

Flat Brick Anchor

Add to cartWe are fabricating flat brick anchors in various materials and grades by using sheet metal.Made from heat-resistant materials, it has a flat, plate-like shape that offers a broad surface area for attachment, ensuring a stable hold on the brick lining. This design helps accommodate thermal expansion, reducing the risk of brick movement or dislodgement, and maintains the structural integrity of the refractory lining under extreme heat and mechanical stress.

Material: :heat-resistant steel(1Cr18Ni9Ti) SUS321,304 Stainless Steel,310 Stainless Steel,316 Stainless Steel,Inconel,Carbon steel

Surface: As finished

Size: As per drawing

Brand: Unbranded/Generic

Application: Industrial Furnaces and Kilns,Petrochemical and Chemical Plants,Power Generation,Heat Treatment Facilities,Cement and Lime Kiln

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

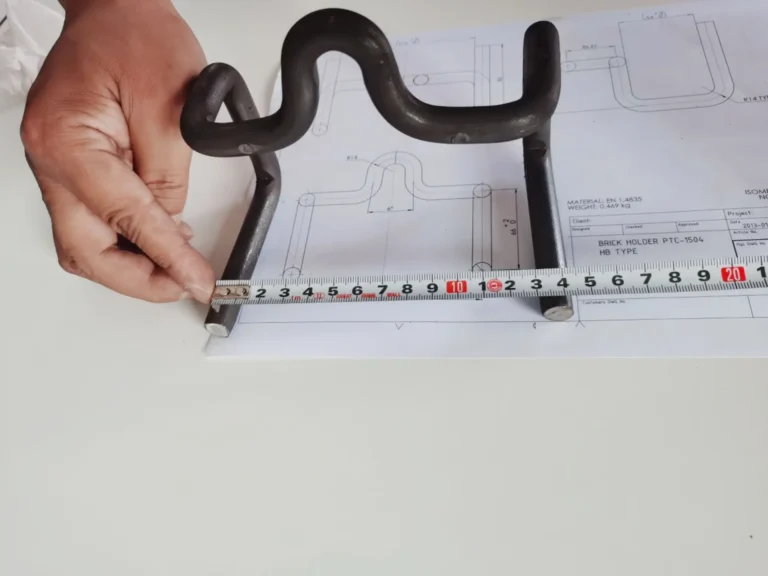

Round Stainless Steel Brick Anchor

Add to cartA Round Bar Brick Anchor is a metal device used to secure brick refractory linings in high-temperature environments, such as furnaces, kilns, and boilers. Made from heat-resistant alloys, this anchor consists of a round bar designed to hold refractory bricks firmly in place against the interior walls of industrial equipment. The round bar shape provides flexibility and strength, accommodating thermal expansion and preventing the bricks from shifting or falling out during operation, thus maintaining the structural integrity and efficiency of the lining.

Material: :heat-resistant steel(1Cr18Ni9Ti) SUS321,304 Stainless Steel,310 Stainless Steel,316 Stainless Steel,Inconel,Carbon steel

Surface: As finished

Size: As per drawing

Brand: Unbranded/Generic

Application: Industrial Furnaces and Kilns,Petrochemical and Chemical Plants,Power Generation,Heat Treatment Facilities,Cement and Lime Kiln

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

V shape Round Refractory Anchors

Add to cartV-Shaped Round Refractory Anchors are metal components used to secure refractory linings to the interior surfaces of high-temperature industrial equipment, such as furnaces, kilns, and reactors. The “V” shape provides strong mechanical anchorage and accommodates thermal expansion, while the round design ensures even distribution of stress across the refractory lining. This combination minimizes the risk of cracking or spalling, enhancing the durability and longevity of the refractory material under extreme heat and corrosive conditions.

Material: :heat-resistant steel(1Cr18Ni9Ti) SUS321,304 Stainless Steel,310 Stainless Steel,316 Stainless Steel,Inconel,Carbon steel

Surface: As finished

Size: As per drawing

Brand: Unbranded/Generic

Application: Industrial Furnaces and Kilns,Petrochemical and Chemical Plants,Power Generation,Heat Treatment Facilities,Cement and Lime Kiln

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

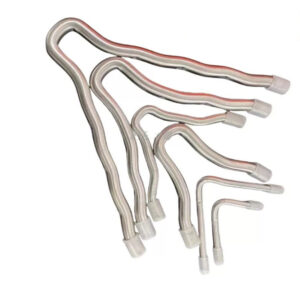

Y shape Flat Refractory Anchors

Add to cartThe Y-shape flat refractory anchor also called splitted Y shaped refractory anchor.We are fabricating these Refractory Anchors in various materials and grades.Typically made from heat-resistant alloys such as stainless steel (e.g., SS 304, SS 310, SS 316) or other high-temperature materials like Inconel and Hastelloy, which can withstand the harsh thermal and chemical environments within furnaces.All anchors can be supplied with plastic caps.

Material: :heat-resistant steel(1Cr18Ni9Ti) SUS321,304 Stainless Steel,310 Stainless Steel,316 Stainless Steel,Inconel,Carbon steel

Surface: As finished

Size: As per drawing

Brand: Unbranded/Generic

Application: Industrial Furnaces and Kilns,Petrochemical and Chemical Plants,Power Generation,Heat Treatment Facilities,Cement and Lime Kiln

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

Y shape Round Refractory Anchors

Add to cartThe Y-shape refractory anchor provides multiple points of contact and support for the refractory material, helping to distribute the load evenly and prevent sagging or detachment.Typically made from heat-resistant alloys such as stainless steel (e.g., SS 304, SS 310, SS 316) or other high-temperature materials like Inconel and Hastelloy, which can withstand the harsh thermal and chemical environments within furnaces.All anchors can be supplied with plastic caps.

Material: :heat-resistant steel(1Cr18Ni9Ti) SUS321,304 Stainless Steel,310 Stainless Steel,316 Stainless Steel,Inconel,Carbon steel

Surface: As finished

Size: As per drawing

Brand: Unbranded/Generic

Application: Industrial Furnaces and Kilns,Petrochemical and Chemical Plants,Power Generation,Heat Treatment Facilities,Cement and Lime Kiln

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

Custom Refractory Anchors Options Available at FASTENMETAL

| Style | V-Anchors,Y-Anchors,Split-Tyne Anchors,Christmas Tree Anchors,Stud weld,Custom Anchor Types according to Clients Requirements. |

| Material | AISI 304, 310, 316, and high temperature alloys like Inconel,If you need other materials,please inquiry us |

| Standard | ASTM A240 / A276,ASTM C 863,ASTM C 1330,ASTM C 1181,EN 10088-2 / EN 10088-3 |

| Material Grade | AISI 304~870°C,AISI 316~900°C,AISI 310~1,100–1,150°C,AISI 330~1,100°C |

| Finishes | Surface finishes purpose is to prevent cracking of the castable. There are typically three types:1.With plastic caps 2.Wrapped with plastic tape 3.Coated with bitumen paint |

| Package | Packed in mesh bags and shipped with wooden boxes |

How We Package Your Anchors

We package each refractory anchor according to customer requirements. The anchors can be fitted with plastic caps, wrapped with plastic tape, or coated with bitumen paint, and are then securely packed in wooden boxes for safe shipment.

Watch How We Produce Anchors

Refractory anchors are mainly used to support and secure refractory linings inside industrial furnaces, kilns, boilers, and petrochemical equipment. FastenMetal is a leading custom fasteners and stamping parts manufacturer in China, main products include refractory anchors and hex mesh.

All our refractory anchors are produced under strict quality standards ASTM, EN10088 ETC, ensuring high strength, excellent heat resistance, and long term performance in demanding high temperature environments. Our refractory anchors are shipped worldwide, including to North America, European countries like Germany, and Southeast Asian countries such as Vietnam. Whether you need bulk orders or custom anchors for industrial furnace projects,we deliver reliable, high quality solutions to satisfy your requirements.

FAQs About Refractory Anchors

Refractory anchors are metal or ceramic components used to secure refractory lining materials (such as castable concrete, bricks, or ceramic fiber) to the steel shell of a furnace or kiln. They are used in high temperature environments to hold the lining in place and prevent it from cracking, collapsing, or separating from the wall due to thermal stress.

For lower temperature applications where budget is the main priority, 304 Stainless Steel is the entry-level option. It is effective up to approximately 1400°F (760°C) and is commonly used for backup linings or standard boilers. However, it is not designed for high heat; pushing it beyond this limit will cause rapid oxidation and scaling, acting much like mild steel would under stress.

For most industrial applications, 310 Stainless Steel is the standard "workhorse" choice. It contains higher levels of Chromium and Nickel, allowing it to withstand temperatures up to 2100°F (1150°C) while forming a protective skin against oxidation. It is generally the best option for furnaces burning coal or oil because it resists sulfur attack better than higher grade alloys. The main downside is that 310 SS can become brittle over time if held at intermediate temperatures, meaning it might snap if hit with a hammer during maintenance.

If your project requires extreme performance, Inconel 601 is the premium solution. It can survive temperatures exceeding 2200°F (1200°C) and offers exceptional resistance to thermal shock, meaning it won't crack during rapid heating and cooling cycles like stainless steel might. While it is significantly more expensive, it remains ductile and strong throughout its lifespan. However, you must avoid Inconel if your fuel source contains high sulfur, as the sulfur will attack the high nickel content and destroy the anchor.

| Material | Industry Application | Temperature Limit | Cost / Budget |

| 304 Stainless Steel | Backup linings, standard boilers | ~1400°F (760°C) | Low Budget |

| 310 Stainless Steel | Gas Forges, Pizza Ovens, Pottery Kilns, Heavy Industrial Boilers (Coal/Oil) | ~2100°F (1150°C) | Standard |

| Inconel 601 | Extreme performance projects requiring high thermal shock resistance | > 2200°F (1200°C) | Premium / Significantly More Expensive |

V-Anchors are the industry standard for almost all general repairs. They are perfect for single-layer concrete linings that are roughly 3 to 10 inches thick. Because the "V" shape spreads out into the material, it holds the lining securely to the wall while still allowing the metal to expand slightly as the furnace heats up. If you are doing a standard job on a boiler or kiln, this is usually the safest and most cost-effective choice.

Y-Anchors are the heavy-duty alternative designed for much thicker or multi-layer walls. Unlike the V-anchor, these have a straight "stem" at the bottom before splitting. This stem allows you to anchor the concrete further away from the steel shell, which is critical if you have a soft insulation layer behind the hard concrete face. You should generally choose a Y-Anchor if your lining is thicker than 10 inches or if you need extra strength to support a heavy load.

Crook Anchors (often called J-Hooks) are specialized tools for tight spaces or very thin linings. A standard V-anchor is often too wide or tall for a lining that is less than 2 inches thick, so the Crook anchor is used instead because of its compact, low-profile shape. Unless you are working with a very thin patch or specific brickwork, you will likely not need this type.

Refractory anchors typically "melt" or corrode not because the steel was bad, but because there was a mismatch between the metal alloy chosen and the specific environment inside your furnace.

The most common reason for anchors appearing to melt is Temperature Overload, which is actually rapid oxidation. If you use a lower-grade alloy like 304 Stainless Steel in a furnace that runs hotter than 1400°F, the metal cannot form a protective skin. Instead, it effectively "rusts" at high speed, scaling off layers until the anchor becomes thin, weak, and eventually disintegrates or snaps under the weight of the lining. It looks like it melted, but it actually burned away.

However, if your anchors are rotting away at temperatures they should technically be able to survive, the culprit is likely Chemical Attack from your fuel source. This is frequently seen in waste oil heaters or incinerators. For example, if your fuel contains Sulfur, it can attack high-nickel alloys (like Inconel) and turn them into a low melting sludge. Similarly, if you are burning waste that contains plastics (chlorine), the chemical reaction can eat through standard stainless steel in a fraction of its expected lifespan.

Finally, "melting" can occur due to insufficient spacing or insulation failure. If the refractory lining cracks or thins out, the anchors get exposed to the direct flame rather than being buried safely inside the concrete. Once exposed to the direct path of the burner, the metal temperature spikes far beyond the wall temperature, causing localized melting even if the rest of the furnace is operating normally.

Our MOQ is one full pallet, depending on the product type.

We also offer samples so you can check the quality before placing a bulk order.

What Customers Say

Still not finding what you’re looking for? For metal parts that are unavailable as standard products, or for very specific requirements, we can manufacture custom metal parts and fixings exactly to your specifications or drawings.