- +86 18015401692

- sales@fastenmetal.com

Trusted by Over 1000 Customers All Over the World

Titanium Screws&Bolts

Titanium Fasteners features low-density, Corrosion resistance and high tensile strength. FastenMetal,Ltd is one of the best Titanium Screws&Bolts Manufacturers In China. We offer custom titanium screws&bolts to meet different grades and specifications.

- 2 Self-owned Factories

- ISO 9001:2015 certificated

- Hundreds of Suppliers

Gallery of Titanium Screws&Bolts

-

TA2 Titanium Philips Button Screws DIN963

Add to cartOur Titanium Philips Button Screws are screws made from pure titanium TA2 that feature a Philips drive (cross-shaped socket) and a button head design. Our Titanium Philips Button Screws are available in diameters from M4 to M16 to suit various grip ranges.Non-standard sizes, materials and finishes are available to order as specials, including small volume manufacture, modifications and bespoke parts made to drawings. Minimum order quantities apply.

Material: TA2 Titanium

Grade:12.8

Standard:DIN963

Size:M4-M20(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

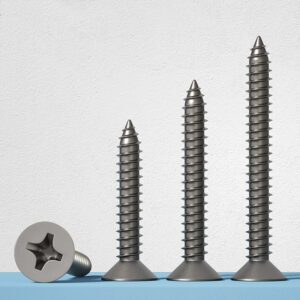

TA2 Titanium Self Tapping Wood Screws

Add to cartTitanium Self Tapping Wood Screws as a type of high-performance fastener, play a important role in modern industry. The manufacturing process of these screws combines precise machining and heat treatment techniques. With a unique thread design and optimized thread profile, these screws can be directly driven into metal sheets without the need for pre-drilling. Additionally, through specialized heat treatment processes, the screws achieve a perfect balance of hardness and toughness, ensuring their stability during use.Our titanium self tapping wood screws are available in diameters from M3 to M6, with various lengths to suit your specific needs. We also offer customization services, allowing you to provide drawings or specifications for tailored designs. Whether you require standard sizes or bespoke solutions, our team is equipped to deliver precision-manufactured screws to meet your requirements.

Material: TA2 Titanium

Grade:12.8,10.8

Standard:DIN912

Size:M3-M6(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

TC4 Titanium Wheel Bolts

Add to cartTC4 titanium wheel bolts are a high-performance, lightweight, and durable solution for securing wheels on vehicles. Made from TC4 titanium alloy, which is known for its excellent strength-to-weight ratio and resistance to corrosion, these bolts are often used in high-end automotive applications, including racing cars, luxury vehicles, and motorcycles.FastenMetal LTD custom titanium fasteners from Printings. For quotes,inquiries,or custom bolts and nuts request, please feel free to click the button”get a free quote”.Material: TC4 Titanium

Grade:12.8,10.8

Standard:DIN912

Size:M5-M16(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

TA2 Titanium Bolts and Nuts DIN933

Add to cartTitanium bolts and nuts are fasteners made from titanium, a lightweight, strong, and corrosion-resistant metal. These fasteners are widely used in industries where performance under extreme conditions is critical, such as aerospace, automotive, marine, medical, and sports equipment manufacturing.Our Titanium Bolts and Nuts are available in diameters from M4 to M36, with various lengths to suit your specific needs. We also offer customization services, allowing you to provide drawings or specifications for tailored designs. Whether you require standard sizes or bespoke solutions, our team is equipped to deliver precision-manufactured bolts to meet your requirements.Material: TA2 Titanium

Grade:12.8,10.8

Standard:DIN933

Size:M5-M36(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

Titanium Socket Button Screws DIN912

Add to cartTitanium socket button screws are characterized by their high strength and lightweight properties, making them widely used in various fields, created to DIN912.They are widely used in aerospace, aviation, and other high-end industries.Our titanium socket button screws are available in diameters from M4 to M16, with various lengths to suit your specific needs. We also offer customization services, allowing you to provide drawings or specifications for tailored designs. Whether you require standard sizes or bespoke solutions, our team is equipped to deliver precision-manufactured screws to meet your requirements.Material: TA2 Titanium

Grade:12.8,10.8

Standard:DIN912

Size:M5-M16(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

Titanium Brake Caliper Bolts Kit

Add to cartTitanium Brake Caliper Bolts Kit is a high-performance upgrade featuring lightweight, durable titanium bolts designed for brake calipers. These bolts resist corrosion, provide excellent strength, and reduce unsprung weight, enhancing braking efficiency and vehicle handling.Our titanium brake caliper bolts are available in diameters from M5 to M10 to suit various grip ranges.Non-standard sizes, materials and finishes are available to order as specials, including small volume manufacture, modifications and bespoke parts made to drawings. Minimum order quantities apply.Material: TC4 Titanium

Grade:12.8

Standard:DIN912

Size:M5-M10(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

TC4 Titanium Self Tapping Motorcycle Screws

Add to cartTC4 Titanium Self-Tapping Motorcycle Screws are premium fasteners made from TC4 titanium, known for its excellent strength, lightweight, and corrosion resistance. Designed specifically for motorcycles, these screws feature a self-tapping design that eliminates the need for pre-threading, ensuring quick and secure installation. Titanium Motorcycle Screws also play a decorative role in motorcycle customization.Our titanium Motorcycle screws are available in diameters from M4 to M16 to suit various grip ranges.Non-standard sizes, materials and finishes are available to order as specials, including small volume manufacture, modifications and bespoke parts made to drawings. Minimum order quantities apply.

Material: TC4 Titanium

Grade:12.8

Standard:DIN912

Size:M1.5-M16(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

Knurled Socket Countersunk Titanium Screws

Add to cartKnurled socket countersunk titanium screws are high-performance fasteners made from titanium, known for their lightweight, strength, and corrosion resistance. They feature a knurled head for better grip during installation, a socket drive for secure tightening, and a countersunk design for a flush finish, making them ideal for precision engineering, automotive, aerospace, and high-end applications. Our knurled socket countersunk titanium screws are available in diameters from M4 to M16 to suit various grip ranges.Non-standard sizes, materials and finishes are available to order as specials, including small volume manufacture, modifications and bespoke parts made to drawings. Minimum order quantities apply.Material: TA2 Titanium

Grade:12.8

Standard:DIN912

Size:M5-M16(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

TA2 Titanium Hex Bolts DIN985

Add to cartTitanium hex bolts are an important kind of high strength fasteners with a hexagonal head designed for tightening with a wrench or socket.We specialize in producing high-quality titanium hex bolts designed to meet the needs of diverse industries.FastenMetal LTD custom titanium fasteners from Printings. For quotes,inquiries,or custom bolts and nuts request, please feel free to click the button”get a free quote”.

Material: TA2 Titanium

Grade:12.8

Standard:DIN985

Size:M5-M80(Other sizes, please inquiry us)

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

-

Titanium Sex Bolts for Handlebar

Add to cartTitanium Sex Bolts are high-strength, lightweight fasteners designed to securely attach handlebars to bikes or other equipment. Made from durable, corrosion-resistant titanium, these bolts offer excellent strength-to-weight ratio, making them ideal for performance-focused applications. The interlocking male and female parts provide a firm connection, while the titanium material ensures long-lasting durability, even in tough environments. These sex bolts are perfect for riders seeking a secure, reliable, and lightweight solution for their handlebar assembly.Non-standard sizes and specials are available to order.Please click button to inquiry.

Material: Titanium

Standard:GB

Finish: Color Plated

Size:M3-M20

Strength Grade:Grade8.8,12.9

Deprecated: preg_replace(): Passing null to parameter #3 ($subject) of type array|string is deprecated in /home/u101520528/domains/fastenmetal.com/public_html/wp-includes/kses.php on line 1807

Still not finding what you’re looking for? For fasteners that are unavailable as standard products, or for very specific requirements , we can manufacture custom titanium fasteners and fixings exactly to your specifications or drawings.

Guide to Titanium Fasteners

Titanium Bolts vs. Stainless Steel Bolts

1.Titanium alloy bolts have more than twice the tensile strength of Stainless Steel Bolts, making them better suited for applications requiring high strength. Additionally, titanium bolts are much lighter, with a weight roughly half that of stainless steel. This is more suitable for situations where need light weight.

2.Titanium bolts&screws offer excellent strength and corrosion resistance, but they are more difficult to produce, so it increases the cost of titanium bolts.

3.Titanium bolts outperform stainless steel bolts in resisting corrosion in environments with acids, alkalis, and oxidizing agents. They can maintain long-term performance in such harsh conditions.

Titanium bolts&screws surpass general stainless steel bolts in terms of strength, weight, and corrosion resistance, but their production challenges make them more expensive. Choosing the right bolt depends on the specific requirements of the application.

Which is Better: Pure Titanium Fasteners or Titanium Alloy Fasteners?

Pure titanium fasteners and titanium alloy fasteners each have their own pros and cons. Choosing the right one depends on your specific needs and the environment in which they will be used.

The primary differences lie in the material composition and performance. Pure titanium fasteners are made by pure titanium, offering advantages such as being lightweight, high strength, excellent chemical stability, corrosion resistance, and heat resistance. However, they are more expensive, harder to manufacture, and prone to thread stripping.

Titanium alloy fasteners, on the other hand, are made by adding other metal or non-metal elements to titanium. While this increases material costs, it enhances properties like heat resistance and low-temperature performance.

Both types of fasteners are widely used in industries such as medical, aerospace, and precision engineering due to their excellent performance. Pure titanium fasteners excel in high-pressure environments thanks to their high strength, low density, and good compressive properties. Meanwhile, titanium alloy fasteners, with their superior heat and cold resistance, are better suited for applications in extreme temperature conditions.

What types titanium materials do you offer?

The most common materials include TA2, TA4, and TC4. TA2 and TA4 are industrial pure titanium. There are also TA1 and TA3, where the higher the number, the higher the content of impurities like steel. This results in reduced ductility but increased tensile strength and hardness. For example, TA2 has a tensile strength of over 400 MPa, while TA4 can reach over 600 MPa. TC4, on the other hand, is a titanium alloy with a tensile strength of over 900 MPa.