In high pressure and high temperature bolted joints, selecting fasteners is a very important and careful decision.A bolt is only as reliable as the nut paired with it.That’s why ASME A193 B7 bolts are almost always matched with ASTM A194 Grade 2H nuts across industries like oil & gas, petrochemical, power generation, and pressure piping.In this article, we’ll break down why A193 B7 bolts are designed to work with A194 2H nuts, how this combination meets ASME and ASTM code expectations, and what engineers and buyers need to know to avoid costly specification mistakes in real world applications.

1. What are ASTM A193 B7 Bolts & A194-2H Nuts?

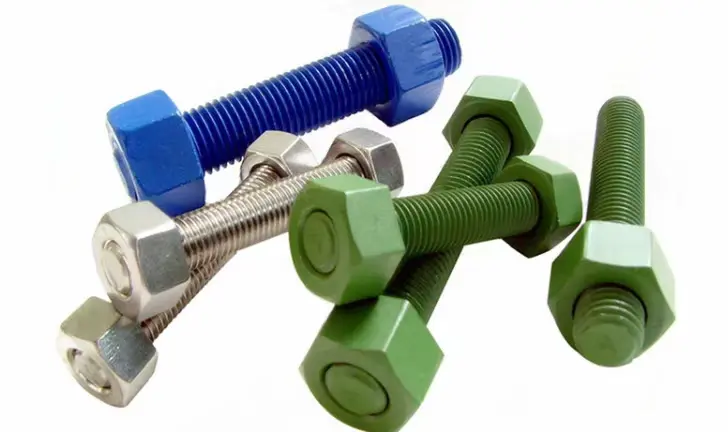

ASTM A193 Grade B7 stud bolts or bolts are high strength alloy steel fasteners specifically for high temperature and high pressure service. They are typically supplied as stud bolts or threaded rods and are produced through a quench and temper heat treatment process, which gives them excellent tensile strength, toughness, and resistance to mechanical stress. Because of these properties, A193 B7 bolts are widely used in important applications such as flanged joints, pressure vessels, boilers, and piping systems.

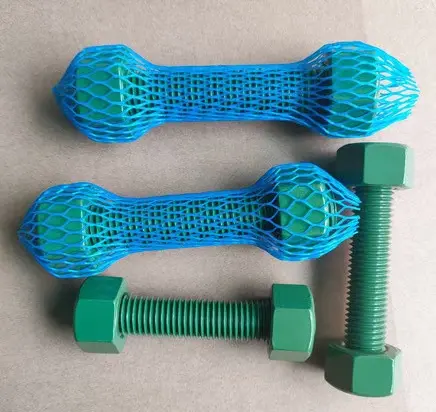

ASTM A194 Grade 2H nuts are heavy hex nuts engineered to be used with high strength bolts like A193 B7. These nuts are also heat treated to achieve the required strength and hardness, ensuring they can safely withstand the loads applied by B7 bolts without thread stripping or deformation. The A194 specification focuses on nut performance in high temperature and high pressure environments, making Grade 2H the standard companion nut for B7 bolts

Together, ASTM A193 B7 bolts and ASTM A194 2H nuts form a matched fastening system that provide reliable clamping force, consistent preload, and long term joint integrity in demanding industrial conditions.

2.Why A193 B7 and A194-2H Are Matched Together?

The pairing of ASTM A193 B7 bolts with ASTM A194 Grade 2H nuts is based on two fundamental engineering principles: strength compatibility and controlled thread clearance.

First, this combination is designed to prevent thread stripping. In a properly engineered bolted joint, the nut must have strength equal to or slightly higher than that of the bolt. This ensures that, under overload conditions, the bolt will fail in tensile fracture before the nut threads shear or strip. A bolt fracture is a visible and predictable failure mode, while thread stripping is far more difficult to detect and poses a greater safety risk.

Second, the pairing helps reduce the risk of galling and seizing at elevated temperatures. Both bolts and nuts expand when exposed to heat. If the thread clearance is too tight, thermal expansion can cause the threads to bind or seize. Conversely, excessive clearance reduces joint stiffness and load stability. The B7 2H system is designed to balance these two concerns.

2.Applications:

The combination of ASTM A193 B7 bolts and ASTM A194 Grade 2H nuts is widely used in applications where high strength, elevated temperature resistance, and reliable preload are critical. This pairing is considered the industry default for many pressure containing and high temperature bolted joints.

1. Pressure Piping and Flanged Connections

B7 bolts with 2H nuts are commonly used in ASME B16.5 and B16.47 flanges for:Oil and gas pipelines,Refineries and petrochemical plants,Chemical processing facilities.They provide stable clamping force under internal pressure and thermal cycling, making them suitable for critical flange joints.

2. Pressure Vessels and Heat Exchangers

In pressure vessels, reactors, and heat exchangers, fasteners are exposed to high internal pressure and elevated operating temperatures. The B7 2H combination ensures controlled preload,Resistance to stress relaxation and Safe performance during start up and shutdown cycles.

3. Power Generation Equipment

B7 bolts and 2H nuts are widely used in Steam piping systems,Boilers and Turbine casings and auxiliary equipment.

Their ability to maintain joint integrity at high temperatures makes them suitable for both fossil-fuel and thermal power plants.

4. Oil & Gas Upstream, Midstream, and Downstream Facilities

Across drilling platforms, refineries, and processing plants, this fastener pairing is used in Valve assemblies,Pump housings

and Compressor systems.The combination performs well in high pressure, high temperature service where safety and reliability are critical.

3.ASTM A193 B7 & ASTM A194 2H Specifications Table:

| Item | ASTM A193 Grade B7 (Bolt / Stud) | ASTM A194 Grade 2H (Nut) |

|---|---|---|

| Standard | ASTM A193 / ASME SA193 | ASTM A194 / ASME SA194 |

| Fastener Type | Stud bolts, threaded rods, bolts | Heavy hex nuts |

| Typical Material | Chromium-molybdenum alloy steel (Cr-Mo) | Carbon steel or alloy steel |

| Heat Treatment | Quenched and tempered | Quenched and tempered |

| Minimum Tensile Strength | 860 MPa (125 ksi) | Designed to match B7 bolt strength |

| Minimum Yield Strength | 720 MPa (105 ksi) | N/A (nut specified by proof load) |

| Proof / Guaranteed Load | — | Controlled to be ≥ mating B7 bolt |

| Hardness Range | Typically 35–40 HRC | Typically 24–35 HRC (controlled to prevent thread stripping) |

| Thread Series | UNC or 8UN (commonly 8UN for pressure service) | Matching UNC or 8UN |

| Thread Tolerance | Standard external thread | Enlarged internal thread pitch diameter |

| Max Recommended Service Temp. | ~538°C (1000°F) | ~538°C (1000°F) |

| Typical Applications | Flanges, pressure vessels, piping, valves | Companion nut for B7 bolts |

| Common Industries | Oil & gas, petrochemical, power generation | Oil & gas, petrochemical, power generation |

| Common Finishes | Plain, black, zinc plated, HDG, PTFE/Xylan | Plain, black, zinc plated, HDG, PTFE/Xylan |

| Matching Pair | Must be paired with A194-2H | Designed specifically for A193-B7 |

Selecting fasteners for high pressure and high temperature applications is not simply a matter of strength,it is about system compatibility and long term reliability. The proven pairing of ASTM A193 B7 bolts with ASTM A194 Grade 2H nuts is the result of careful engineering, balancing tensile strength, heat treatment requirements, and controlled thread clearances.

By matching a high strength, quenched and tempered alloy steel bolt with a nut designed to equal or exceed its load capacity, this combination ensures predictable failure modes, minimizes the risk of thread stripping, and maintains stable preload under thermal cycling. The enlarged internal thread tolerance of 2H nuts further enhances performance at elevated temperatures by reducing the likelihood of thread seizure while preserving joint integrity.

For industries such as oil and gas, petrochemical processing, power generation, and pressure equipment manufacturing, the B7 2H combination remains the industry standard for a reason. When specified and installed correctly, it delivers dependable performance, improved safety, and long service life in some of the most demanding operating environments.

In important bolted joints, choosing the correct bolt and nut pairing is not optional,it is nessesory.