An embedded plate is simply a steel plate with anchors attached to it,it sits inside concrete. The plate is placed in the formwork before the concrete is poured. It becomes part of the concrete after the concrete becomes hard. The plate often comes with welded anchors, studs, or rebars. These fasten the plate to the concrete. The plate gives builders a strong point for welding or bolting steel parts in the future. Many buildings, bridges, and industrial structures use embedded plates because they offer strong and simple connections.Today’s blog is help you to explore how to install embedded parts in concrete construction, how to choose and their applications.

Understanding the Importance of Embedded Plates

Embedded plates are absolutely important when we build with concrete. Think of them as the strongest glue that lets two different materials, steel and concrete, work together perfectly. They are special metal plates that have anchors attached, and they are carefully set into the molds before the concrete is poured. This is critical because the main job of these plates is to safely transfer all the heavy forces like the massive weight of a roof beam or the strong pulling of wind from the steel framework right into the solid, heavy concrete foundation. This method is much better and stronger than trying to anchor parts later. Also, these plates make the building process much quicker and more organized. Once the concrete hardens, workers can easily and precisely weld or bolt the steel parts onto the exposed plate. This guarantees that all the pieces line up correctly, saving a lot of time and making sure the entire building is structurally sound, stable, and safe for many years.

Types of Embedded Parts

There are several types of embedded parts used in concrete construction, It usually means metal components that are placed into the concrete formwork before the concrete is poured. Here are some of the most common types:

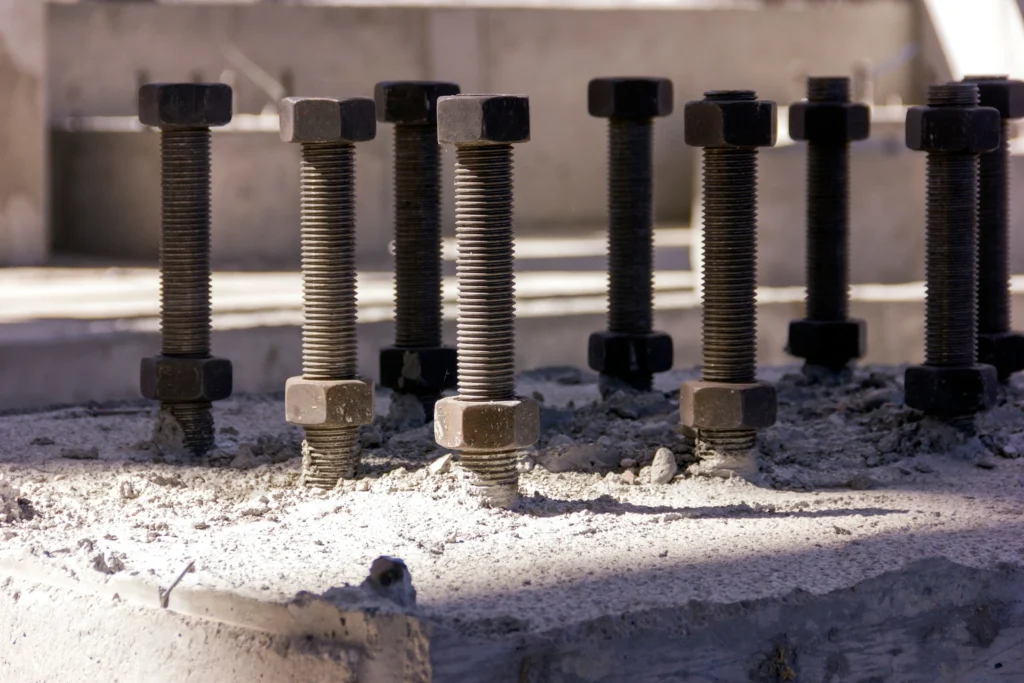

1. Embedded Plates (or Cast in Plates)

The most common type for major construction connections is the embeds, which is essentially a thick, flat piece of steel plate with anchorsmost often headed studs welded to its back. This assembly is positioned in the formwork so that the plate’s smooth face is flush with the finished concrete surface. The primary purpose of the embedded plate is to provide a preplanned, high strength connection point where structural steel elements, like columns, beams, or bracing, can be securely welded or bolted later on. They are crucial for transferring massive structural loads (tension, shear, compression) from the external steel structure safely into the large mass of concrete, ensuring the structural stability of the entire building.

2. Reinforcing Bars (Rebar) and Mesh

Rebar and mesh are the most basic embedded parts. They are necessary for making concrete strong. Rebar is long steel bars with ridges, and mesh is a grid made of thinner steel wire. Concrete is strong when you push on it, but it breaks easily when you pull on it. These steel parts go inside the concrete to stop it from cracking or pulling apart. They work like an inner skeleton that holds the concrete together, which makes the concrete material much more durable and strong overall.

3. Threaded Inserts and Anchor Channels

These parts are often used for smaller jobs and when things might need to be moved a little bit. A threaded insert is just a small metal sleeve with threads on the inside, like a simple nut. It is set into the wet concrete. Later, you can easily screw a bolt into it to hold things like railings or small machines. Anchor channels are long, U-shaped steel tracks. You can slide a special bolt along this track and lock it into place anywhere you need it. This allows you to easily adjust the exact spot for connecting things like wall panels.

4. Angle Embeds and Edge Protectors

Angle embeds are pieces of steel bent into an “L” shape that are stuck into the concrete along an edge or corner. One side is held by the concrete, and the exposed side gives you a straight, sturdy point to attach steel supports. The other job they do is acting as an edge protector. When heavy objects like forklifts hit the corner of a concrete slab, the steel angle takes the blow and stops the concrete from chipping or breaking apart. They keep the edges looking good and prevent major damage in busy areas.

What Thickness / Plate Size / Anchor Types Should I Choose?

Choosing the right thickness for your plate, its size, and the best anchor type is very important for safety and strength. You must base all these choices on the load, or the total amount of weight and force, that the plate must hold. If the load is small, you can use a thinner, smaller plate with fewer anchors. But if the load is very heavy, you must choose a much thicker and bigger plate so it will not bend. For anchors, the most common type is the headed stud, which looks like a small metal rod with a wide head that is welded to the plate. You must make sure these studs are long enough and there are enough of them to grip the concrete tightly and keep the plate from pulling out. Basically, the heavier the load, the bigger and stronger every part of the embedded plate system needs to be.

How to Properly Install Embed Plates to Avoid Misplacement?

Proper installation is a big challenge on the job site. If the plate is in the wrong place, the entire structure might not fit.

Check Dimensions:First, measure carefully. Make sure the plate is in the exact spot and height shown on the blueprints.

Use Templates and Supports: Plates should be fixed to the formwork (the mold for the concrete) using a template. This template is often a piece of wood that holds the plate perfectly in position.

Tie to Rebar: The plate assembly is often tied with wire to the surrounding rebar cage to keep it from moving when the concrete is poured.

Watch During Pour: When the concrete is poured, the wet mix can push the plate out of place. Watch the plate and fix it quickly if it moves.

Benefits of using embedded parts in concrete construction

The benefits of using embedded parts in concrete construction are significant, primarily centered on achieving a stronger, more reliable, and more efficient building process.

1. Superior Structural Integrity and Strength

Embedded parts are cast directly into the concrete, meaning they become a unified, monolithic part of the structure.

Reliable Load Transfer: They ensure a highly predictable and secure way to transfer massive loads (like shear, tension, and compression) from the attached steel structures into the concrete mass. The strong anchors (studs, bolts) are designed to fully engage the concrete’s strength.

Engineered Connection: Connections can be precisely pre-engineered and calculated to meet specific safety factors and building codes. This results in a stronger, more reliable joint than most methods used after the concrete has hardened.

Reduced Damage to Concrete: Unlike drilling into hardened concrete later (post-installed anchors), which can create micro-cracks or weaken the concrete’s integrity, cast-in embeds do not introduce stress after curing.

2. Increased Construction Speed and Efficiency

Embedded plates significantly speed up the construction sequence after the concrete is set.

Fast Assembly: Steel structures (columns, beams) can be quickly and easily welded or bolted onto the exposed embed plates immediately. This eliminates the time-consuming steps of drilling, cleaning, and installing chemical or mechanical anchors for every major connection.

Tolerance and Alignment: Inserts and anchor channels allow for minor adjustments (like sliding a bolt), helping construction crews align heavy steel elements, cladding, or equipment perfectly, even if the concrete pour was slightly off.

3. Versatility and Flexibility

Embedded parts allow the concrete structure to interface with nearly any other material or system.

Multiple Connection Options: They support various connection methods, including welding, bolting, and using threaded rods.

Future Use: They provide pre-determined attachment points for future installation of building utilities, pipe supports, heavy equipment, and non-structural facade systems long after the main concrete work is done.

Conclusion

Embedded plates are very important in building with concrete because they give you many good things. The best thing is that they make the structure much stronger and safer. Since the plates are put into the concrete while it is wet, they become a fixed part of the wall or floor, making a very reliable connection that can hold huge weights and forces. This method is also faster and cheaper for workers, because they can quickly bolt or weld steel beams to the plate later, instead of spending time drilling many holes into hard concrete. Also, these plates let you easily connect different things like heavy machines or railings to the concrete structure. So, embedded parts help make the building strong, easy to finish, and safe for a long time.